The test wavelength of S365 is 320nm-400nm, central wavelength is 365nm. SMT patch technology is used to select high precision and low power digital chip. The detector has been strictly calibrated for spectrum and Angle characteristics, and has stable performance and strong applicability. This UV instrument is used for measuring ultraviolet irradiance in photo-chemistry, aging of polymer materials, detection of damage, UV light source, plant cultivation, and large-scale integrated circuit photo-lithography.

|

| https://www.leduvcuring.com/ |

Technical Parameters :

* Optical Testing Range : 0 - 20000mW/cm2

* Testing Precision : ±5 %

* Resolution Ratio : 0.01 mW/cm2

0.01mj/cm2

* Power Supply : 1200mAH lithium ion battery

* Outside Dimension : main engine : L156*W75*H22(mm)

Probe : L32*W36*H14(mm)

* Photo-sensitive Aperture : ¢8mm

* Standard Line : 1m, the length can be customized

* Sampling Time : 0.5s

* Data Logging : loop through 10sets of data

* Weight : 350g

* Operating Temperature : Host : -10至60°C

Probe : -20至100°C

* Temperature: 120 ° C (C) has been shining under the condition of no more than 20 seconds

* The following probes are available:

A:S254 wavelength range :230nm-280nm;λp:254nm

B:S297 wavelength range :280nm-330nm;λp:297nm

C:S365 wavelength range :320nm-400nm;λp:365nm

D:S395 wavelength range :340nm-420nm;λp:395nm

Characteristics :

1. Spectral and Angle characteristics after strict calibration, good stability.

2. Using microcomputer technology, high precision, low power consumption.

3. Digital liquid crystal display with backlight.

4. The probe is separated from the main engine for convenient replacement of different probes.

5. Memory function, the cycle can store 10sets of data.

6. Number holding function, Hold key, easy to record contrast.

7. Automatic shutdown saves electricity.

8. Instrument built-in rechargeable lithium ion batteries.

9. With its own USB cable charging, it can directly connect to the company USB interface charging.

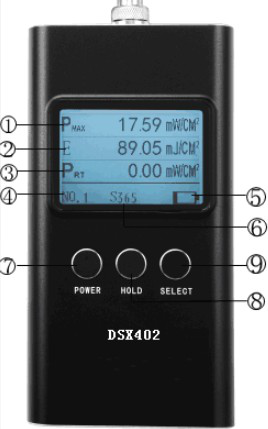

1. Pmax Maximum 8. HOLD hold key

2. E Energy Value (cumulative value)

3. PRT current value 9. SELECT select key

4. NO.1 memory group 10. air interface

5. battery statues 11. cable

6. S365 probe model 12. induction hole

4. NO.1 memory group 10. air interface

5. battery statues 11. cable

6. S365 probe model 12. induction hole

7. POWER ON/OFF

Equipment Maintenance and Attention :

⊙ Calibration period : it is suggested that the calibration period is one year.

⊙ There is a magnet on the back of the instrument probe, which can be attached to the iron plate for easy fixation.

⊙ The instrument should be kept clean when it used, and the probe should be handled lightly to avoid strong vibration, so as to ensure the accuracy of the measurement results.

⊙ Avoid contact with corrosive articles, being soaked in liquid, away from high temperature and high humidity environment.

⊙ Do not connect any object other than the labeled photo-sensitive probe to the main body socket of the instrument to avoid permanent damage to the instrument.