Japan NICHIA 405nm UV LED Lights is 6868 Flat Window 120 degree quartz glass encapsulation, 3D Printer Curing Lamp

Parameters of High Performance 405nm LED Lighting for UV Curing :

Lens

|

Hard quartz glass 120°angle of divergence

|

Forward Current

|

700mA

|

Forward Voltage

|

3.5-3.9V

|

Power Dissipation

|

3.08W

|

Radiant Flux

|

800mW/cm2

|

Peak Wavelength

|

405nm

|

Encapsulation Dimension

|

6868, 6.8*6.8*1.9 L*W*H(mm)

|

Appilcations of NICHIA NCSU035C Ultraviolet LEDs Curing UV Coating :

1. Curing UV Epoxy Resin

2. Special for 3D Printing

Specifications of High Efficiency 405nm NCSU035C SMD-LED UV Lights :

1.Absolute Maximum Ratings

Item

|

Symbol

|

Absolute maximum rating

|

Unit

|

Forward current

|

IF

|

700

|

mA

|

Pulse forward current

|

IFP

|

1000

|

mA

|

Allowable reverse current

|

IR

|

85

|

mA

|

Power dissipation

|

PD

|

2.73

|

W

|

Operating temperature

|

Topr

|

-10~85

|

℃

|

Storage temperature

|

Tstq

|

-40~100

|

℃

|

Junction temperature

|

TJ

|

130

|

℃

|

* Absolution Maximum Ratings at Ts=25℃

* TFP conditions with pulse width ≤10 ms and duty cycle ≤ 10%

2.Initial Electrical / Optical Characteristics

Item

|

Symbol

|

Condition

|

Typ

|

Max

|

Unit

|

Forward voltage

|

VF

|

IF=500mA

|

3.4

|

-

|

V

|

Radiant flux

|

Φe

|

IF=500mA

|

770

|

-

|

mW

|

Peak Wavelength

|

λp

|

IF=500mA

|

405

|

-

|

nm

|

Spectrum half width

|

△λ

|

IF=500mA

|

12

|

-

|

nm

|

Thermal resistance

|

RθJS

|

-

|

4.3

|

5.3

|

℃/W

|

* Characteristics at Ts=25℃.

* Radiant flux value as per CIE 127:2007 standard.

* RθJS is the thermal resistance from the junction to the Ts measurement point.

* It is recommended to operate the LEDs at a current greater than 10% of the sorting current to stabilize the LED characteristics.

3.RANKS

Item

|

Rank

|

Min

|

Max

|

Unit

|

Forward voltage

|

M

|

3.5

|

3.9

|

V

|

L

|

3.1

|

3.5

| ||

Radiant flux

|

P6d22

|

870

|

950

|

mW

|

P6d21

|

800

|

870

| ||

P5d22

|

730

|

800

| ||

P5d21

|

670

|

730

| ||

Peak wavelength

|

U405

|

400

|

410

|

nm

|

* Ranking at Ts=25℃

* Forward voltage tolerance : ±0.05V

* Radiant flux tolerance : ±6.5%

* Peak wavelength tolerance : ±3nm

* LEDs from the above ranks will be shipped. The rank combination ratio per shipment will be decided NICHIA.

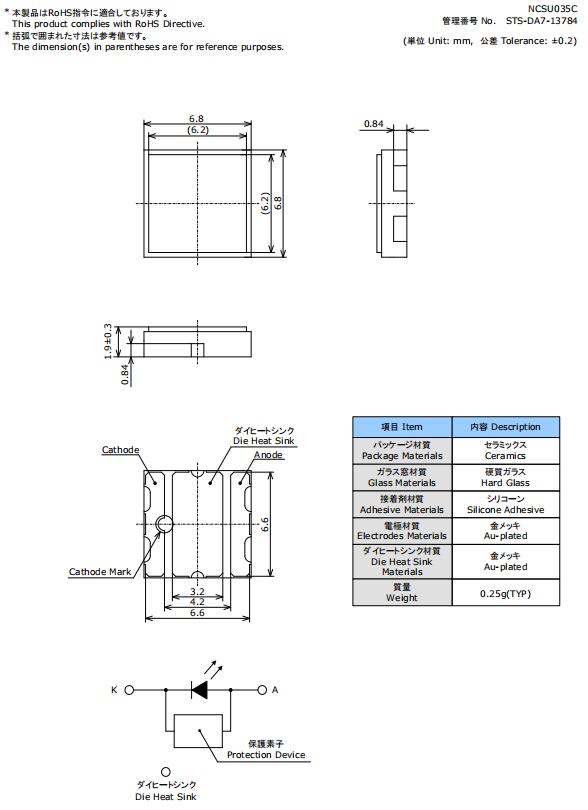

Outline Dimensions of Installing NICHIA Ultraviolet LED Lights for UV Flashlight :

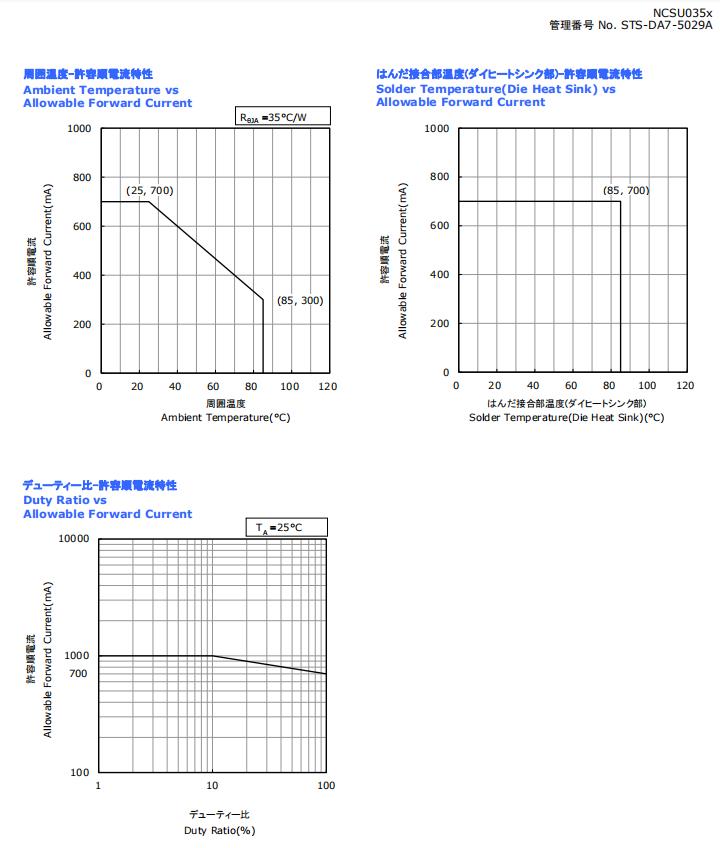

Derating Characteristics of Imported Japan NICHIA UV LEDs Solding PCB :

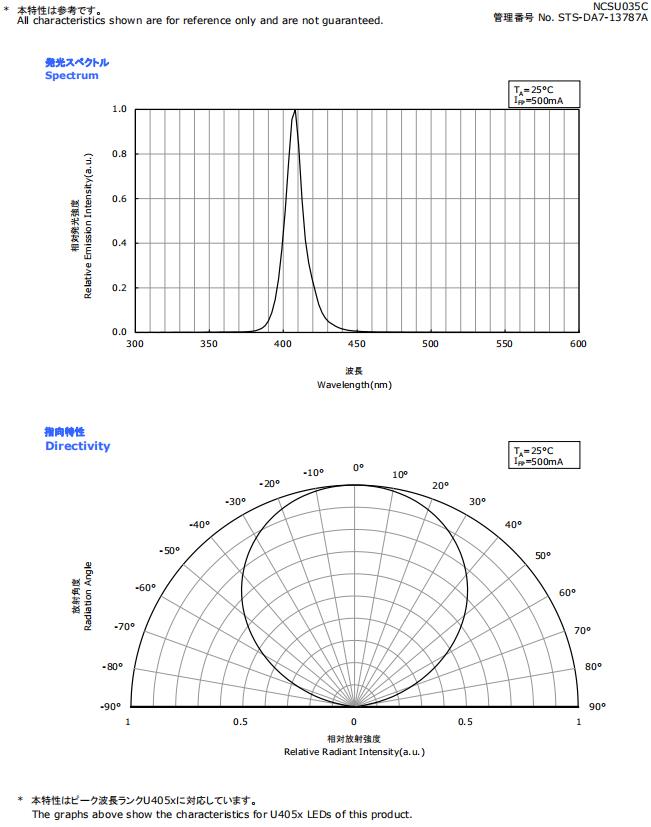

Optical characteristics of NICHIA 405nm Ultraviolet Light Emitting Diodes :

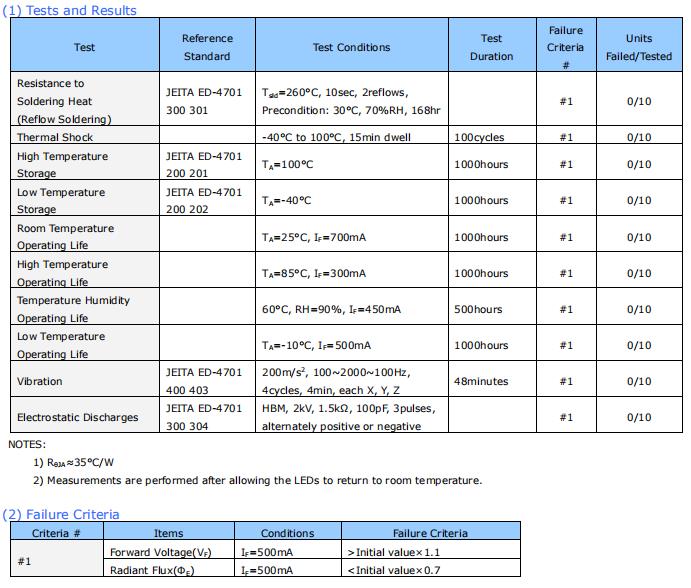

Reliability of NICHIA 405nm UV Flashlight Lights :