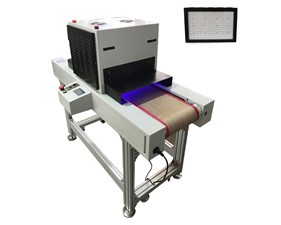

UV LED curing machine, to replace the traditional mercury lamp, low temperature, no ozone, no deep UV, low energy consumption, high efficiency.

UV LED vertical curing machine replaces traditional mercury lamp, built-in UVLED curing light source, low temperature, no ozone, no deep ultraviolet, low energy consumption and high efficiency.

Product Survey

DSX-SL360-290X180-365 / 385/395/405 is a high-performance UVLED curing system, the system includes the controller, UVLED irradiation head and cable. UVLED head with imported high-intensity UV LED integrated UV spectral wavelength of 365nm, 385nm, 395nm, 405nm, the use of forced air cooling, the effective curing area of 300X200mm, support for external signal input and trigger, can be equipped with semi-automatic or fully automated production line .

Specification Parameter

1, luminous body (effective irradiation width): can be customized;

2, UV LED lights from the conveyor belt adjustable distance: 10-50mm;

3, UV LED lamp power density: 800mw / cm2;

4, UV light intensity adjustable: 1% -100%;

5, Reflector: Aluminum reflector built-in imported reflective aluminum, high reflection efficiency, long service life;

6, the conveyor belt width: 300mm;

7, conveyor belt material: Teflon mesh belt or stainless steel mesh for optional;

8, Conveyor speed: 1-10 meters Promise adjustable;

9, LED lamp beads that is bright, without preheating, immediately begin curing work;

10, roller: surface knurling, to ensure smooth delivery;

11, the whole cooling method: air-cooled;

12, machine material: sheet metal;

13, machine appearance: white spray computer

14, the whole specification: 1500L * 580W * 100Hmm;

15, power wiring: 220VAC 50HZ;

No comments:

Post a Comment