Advantages and limitations of UV curing system in the printing industry in recent years, the industry has developed LED UV light source, because of lower energy consumption, curing efficiency is higher, and the supporting LED UV ink composed of LED UV curing technology is becoming printing enterprises to achieve energy saving and environmental protection “new favorite”.

1.Advantages :

A.Lower energy consumption, high effective luminous efficiency, can reduce energy consumption by 70% to 80%.

B.There is no ozone generated in the curing process, and the LED UV light source will not generate short-wave ultraviolet light. Therefore, ozone will not be generated in the curing process. No odor-removing device or exhaust duct and other auxiliary device are needed to maintain a clean working environment.

C.More flexibility, LED UV light source using spot light source, can be combined with the size of the paper, grading set the exposure range.

D.The lamp can be turned on (off) instantly. The traditional UV light source can only be started after 1 minute of preheating and turned off after 4 minutes of cooling. To improve efficiency, many operators usually leave the UV light on all the time, which causes a lot of waste. The LED UV light source can be turned on instantly when printing, which greatly improves the work efficiency.

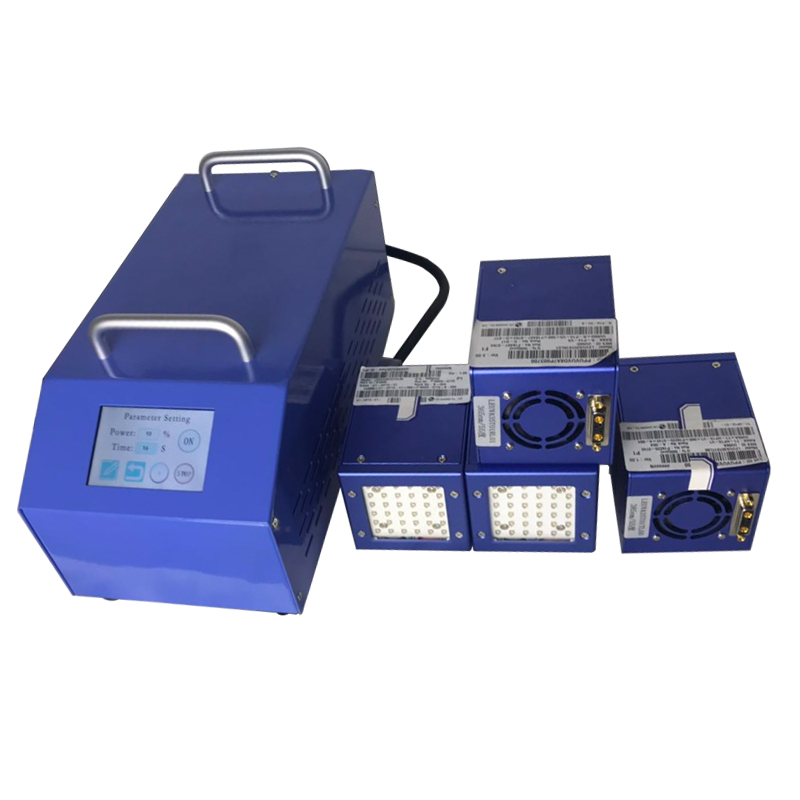

E.Calorific value is small, the Selling Leads UV LED Exposure Equipment for Exposure photo-electric conversion efficiency is high, the tube surface temperature is only about 60°, can effectively prevent the print the contraction deformation due to overheating, so as to achieve high accuracy.

F.Long service life, the service life of LED UV light source can be up to 20,000 ~ 30,000 hours, which is more than ten times of the existing high-pressure mercury lamp and metal halide lamp (1500 hours), and can greatly reduce the number of light source replacement.

2.Limitation

A.Irradiation intensity is weak, if the printing speed is too fast, easy to lead to incomplete ink curing.

B.Can only emit long-wave UV light, not short-wave UV light, so not conducive to UV curing varnish.

C.The price of Energy Saving UV LED Irradiation System for Spot Curing is on the high side.

D.The existing printing press transformation is difficult. Because the LED UV light source irradiation distance is short, it must be closed to the substrate surface irradiation. In order to ensure good ink curing, so the existing printing press transformation has brought great inconvenience.

LED UV ink to make UV ink in LED UV light source can fully cure, in the development process of LED UV ink must be strictly screened raw materials.

1.Photo-initiators that react to ultraviolet light from Ultra High Power UV Curing Light are few. Therefore, photo-initiators with excellent reaction performance need to be selected. LED UV ink photo-initiator nor only need to UV LED Curing Machine emitted by the narrow band UV light can have a strong absorption, but also must achieve the ink surface and internal curing at the same time. Therefore, when choosing LED UV ink photo-initiator, should ensure that the photo-initiator in LED UV light source under the specific wavelength has best absorption characteristics, but also should develop the best ratio of photo-initiator combination, in order to absorb as much as possible the limited UV light. Especially for transparent light oil, it is necessary to find a limited type of light initiator within the scope of light oil yellowing and curing to achieve a balance of light initiator.

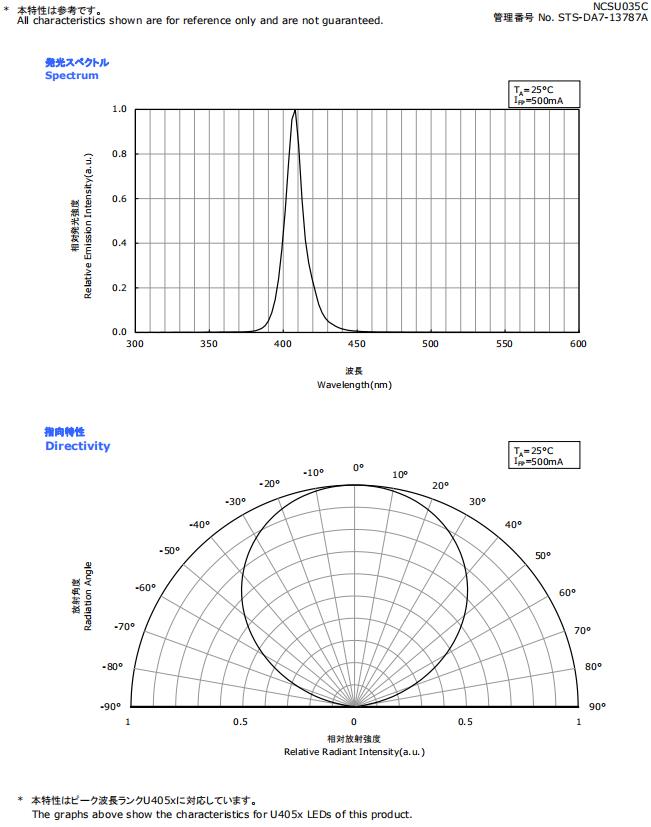

2.Pigment, in offset printing production, we usually use “black blue magenta yellow” color sequence for overprint, the first printed black ink can only through the blue, magenta, yellow ink has become weak UV curing. However, the pigment in the ink film can easily absorb ultraviolet light. Therefore, UV light is usually difficult to reach the inner layer of ink, resulting in ink curing is not complete. For ordinary UV light source, because the spectrum contains short-wave ultraviolet light, so the deep curing of the ink layer is ideal. As for the LED UV light source, because it emits only lone-wave ultraviolet light and a relatively single wavelength, if the absorption wavelength of the pigment in the ink and its coincidence, the ink curing performance will become worse.

Therefore, compared with ordinary UV ink, LED UV ink must choose to use High Performance Ultraviolet Curing Equipment for UV Bonding specific wavelength penetration (absorption) of the best pigment, which is one of the key factors in the development of LED UV ink. At the same time, the use of pigment with better coloring ability, improve the ink color concentration, reduce the amount of printing ink (so as not to affect the curing effect due to the ink layer is too thick), is also an effective means to improve the curing performance of LED UV ink.