LED UV Exposure Curing Equipment, cold light source, non-damaging horn, fast speed curing, not only is appropriative designed for factory manufacturing sound, but also can cure UV glue, UV ink, UV varnish, 3D printing, etc. If your factory manufactures trumpets in bulk, curing horn process can be considered using this type of UV LED Light Curing Systems. Fast curing effect is recognized by many speaks manufacturers.

Controller Parameters of Cold Light Source Ultraviolet Exposure Curing Systems :

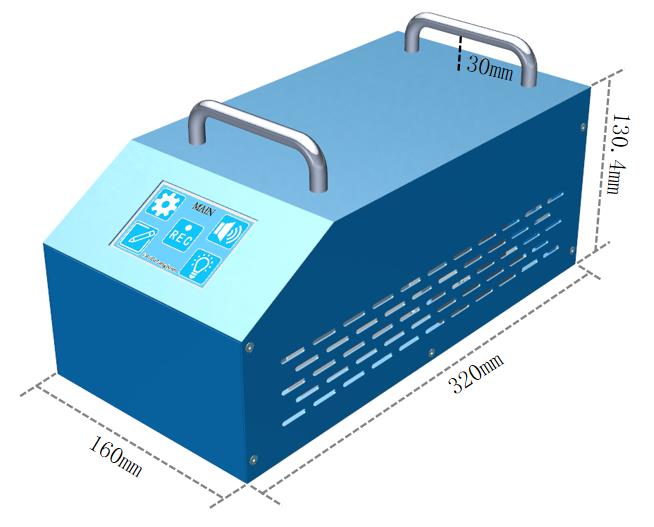

Outside dimension

|

L320*W160*H130mm

|

Power dissipation

|

Lower than 5W in standby mode

|

Cooling

|

Air cooling

|

Input power

|

100-240V AC 50-60 HZ

|

Material / Weight

|

Sheet metal blue paint / 6.4kg

|

Drive the number of luminous heads

|

One mainframe drives two light sources

|

RS232serial communication function

|

Can query and adjust illumination, time, switch

|

Control mode

|

Manual switch control and pedal switch control

|

LED time accumulation

|

Actively record cumulative usage time

|

External terminals

|

It can be connected with single machine, PLC and other equipment for control and working status feedback

|

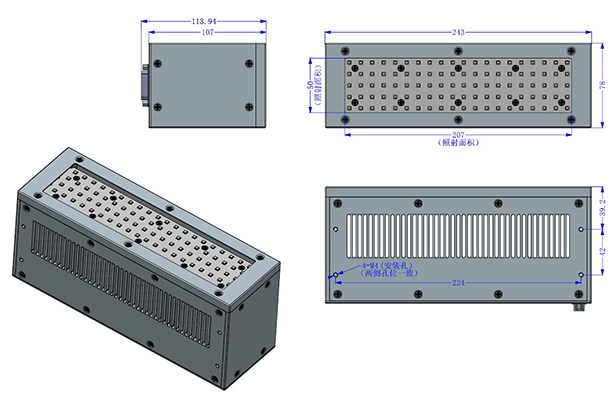

Luminescent Head Specifications of High Intensity UV LED Irradiation Curing Systems for UV Coating :

Luminous Size

|

50 * 200mm

|

Power

|

600W with two heads

|

Outsize dimension

|

L 243*W78*H114mm

|

Recommend highly

|

5 mm

|

Cooling

|

Air cooling

|

Wavelength

|

365 nm-415mm selectable

|

Material / Weight

|

Sheet metal blue paint / 6kg

|

Luminous Power(mW/cm2)

|

1000 @ EIT

|

Predicted service life

|

20000 H

| ||

Display

|

LCD touch screen

|

Cable length

|

2 .5 m

|

No comments:

Post a Comment