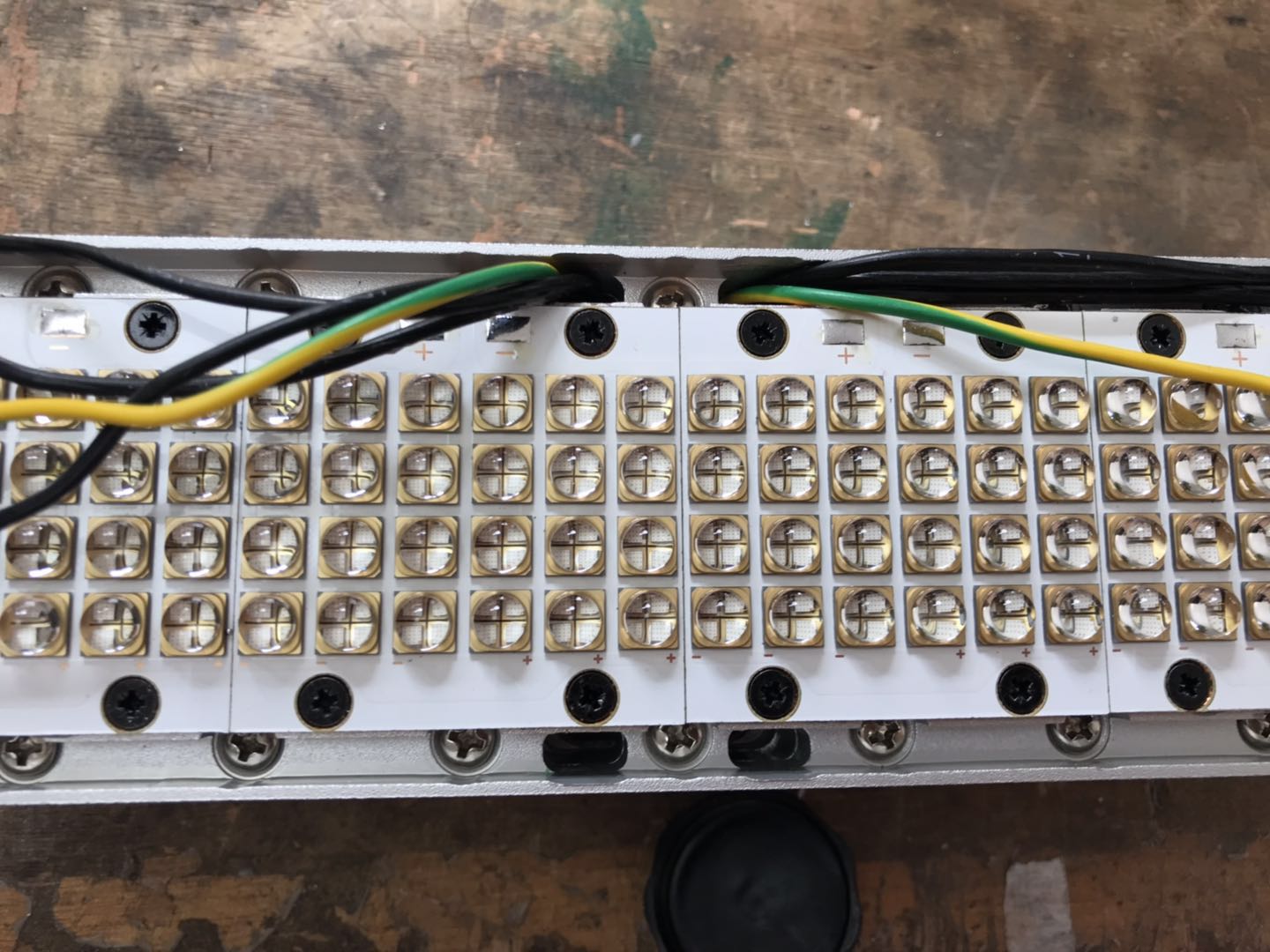

150mm Linear UV Light Light Curing System illuminating, with 365nm 395nm, curing UV glue and UV ink, can set time and illumination, external pedal RS232 and other multi-function.

parameter of Linear UV Curing Machine

Controller specification

shape

|

L320*W130*H130mm

|

weight

|

2.7kg

|

cool down

|

Air cooled

|

Input power

|

100-240V AC 50-60 HZ

|

material

|

Black, gold

|

Number of driving heads

|

One

|

RS232 serial communication

|

Can query and adjust intensity, time, mode

|

Display and operation

|

Touch screen for adjustable time and intensity

|

LED time accumulation

|

Active record cumulative usage time

|

External terminalblock

|

Can be connected with single-chip, PLC and other equipment for control and working status feedback

|

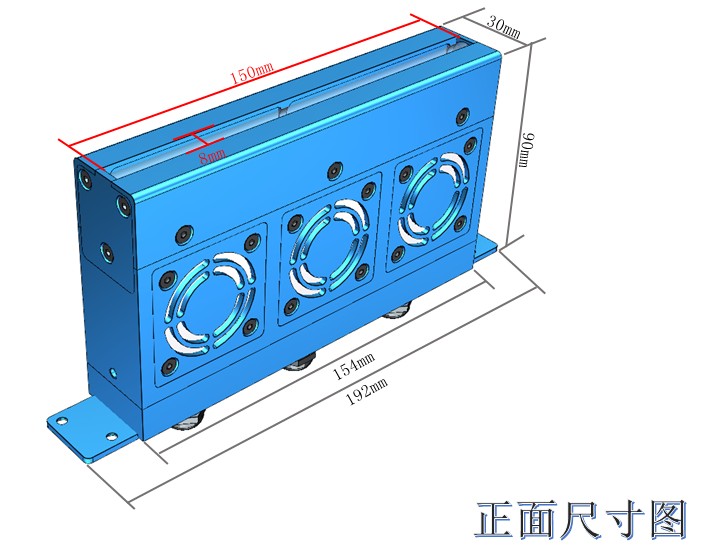

Glow head specifications

Light size

|

150 * 8mm

|

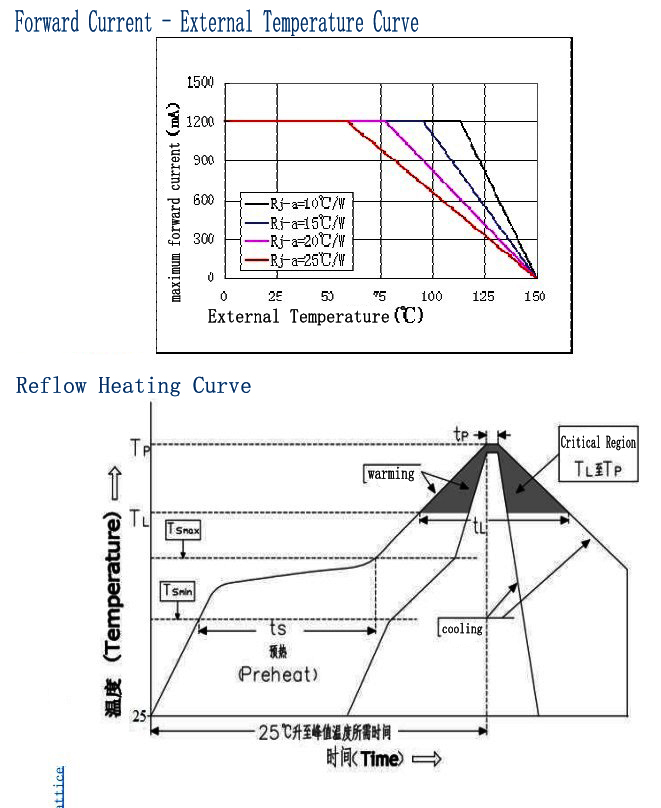

power

|

110W

|

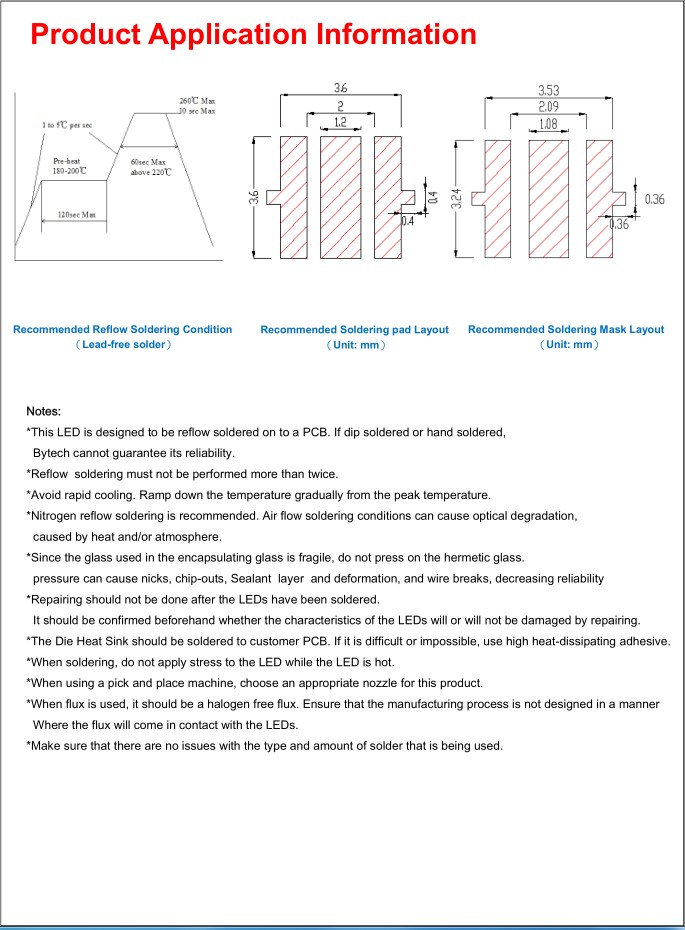

Dimensions

|

L 192*W105*H30 mm

|

Recommended height

|

1-20 mm

|

cool down

|

Air cooled

|

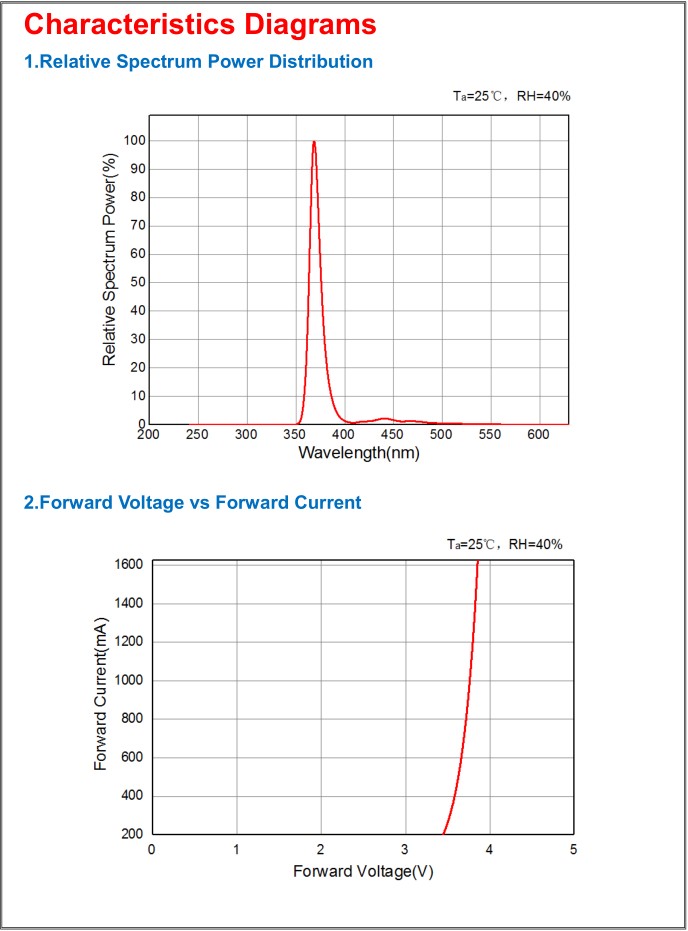

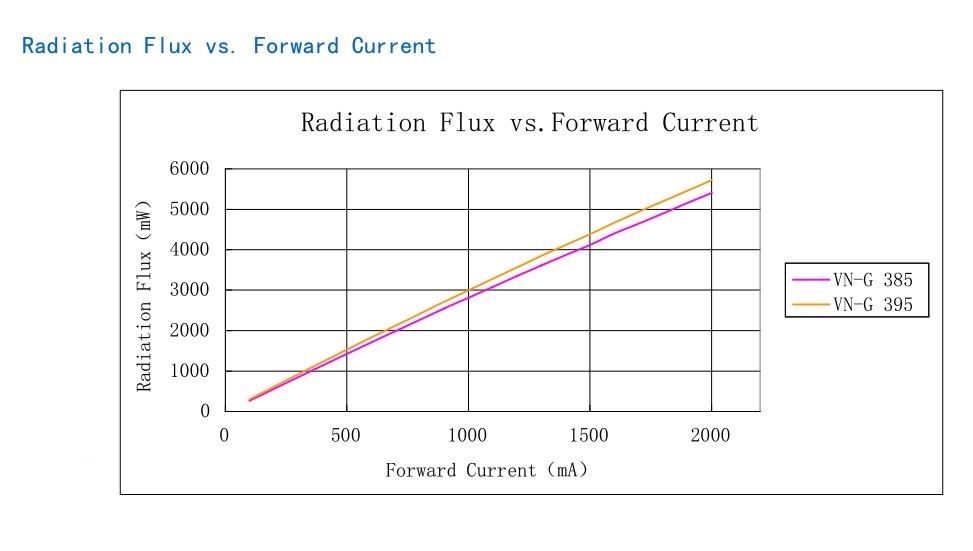

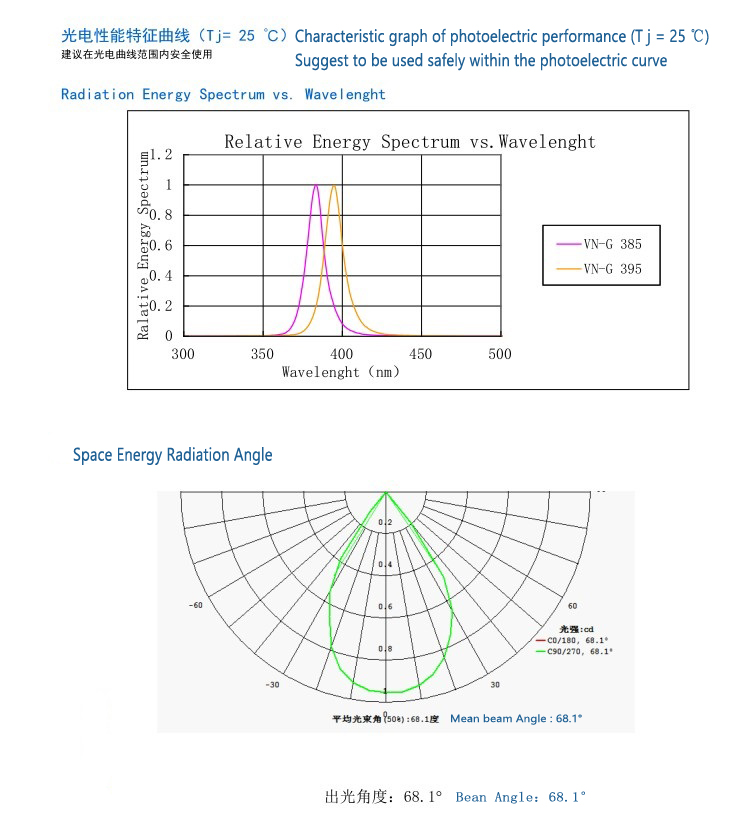

wavelength

|

365 / 385 / 395 / 405

|

Material / weight

|

Sheet metal, blue paint / 0.25kg

|

Luminous power (mW/cm 2 )

|

365nm

|

2800mW/cm2 @ EIT

|

Prediction of service life

|

20000 H

|

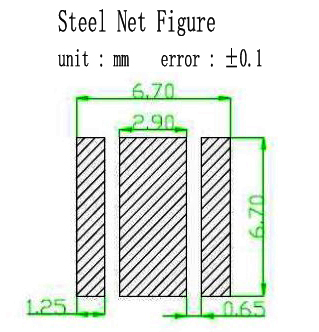

Installation size:

Application field of Small Area LED UV Curing Light

UV LED line source

The UV LED line source is one type of UV LED source, and the line source is a mode that only emits light. It is a long-range UV belt that is output through a specially designed optical lens set to meet the production needs of the edge banding, printing and other fields. Line light source has long life, cold light source, no heat radiation, long life without being affected by opening and closing times, high energy, uniform illumination to improve production efficiency, and no toxic substances are safer and more environmentally friendly than traditional light sources.

UV LED line source use and scope of use:

microelectronics, liquid crystal,PCB, optical communication, optical and other linear light curing;

High-grade furniture UV paint curing;

Printing anti-counterfeiting detection;

Crafts spray curing;

TFT-LCD liquid crystal panel filling port package.

Capacitive screen side curing, edge sealing curing

liquid crystal glue bonding side curing

mobile phone screen refurbished water glue bonding side curing

LED , LCD , OLED screen sealing edge curing

Linear curing, curing slit, the slit adhesive

UV LED line light source used in smart phones

1 , the mobile phone screen and the bezel adhesive phone

2 , phone housing an adhesive

3 , the side key adhesively fixed

4 , the camera positioning of the window

5 , LOGO of Paste

6 , smart phone with cover

7 , of the sound box , smart phone FPC antenna and chassis

8 , camera module between HOLDER and FPC ( FPC bending area)

9 , mobile phone flat motor cable fixed .

10 , fixed phone motherboard

Microelectronics Industry - UV Light Curing Applications

1 , mobile phone component assembly (camera lens, earpiece, microphone , housing , LCD module , touch screen coating, etc.)

2 , hard disk head assembly (gold wire fixing , bearing , coil , die bonding, etc.)

3 , DVD / digital camera (lens , lens bonding, circuit board reinforcement)

4 , motor and component assembly (wire , coil fixed, coil end fixed , PTC / NTC component bonding , protection transformer core)

5 , semiconductor chip (moisture protection coating , wafer mask , wafer contamination inspection , UV tape exposure , wafer polishing inspection)

6 , sensor production (gas sensors, photoelectric sensors, fiber optic sensors, photoelectric encoders, etc.)

7 , laser UV curing application

PCB industry UVLED light curing application

1 , components (capacitors , inductors , various plug-ins , screws , chips, etc.) fixed

2 , moisture-proof potting and core circuit, chip protection , antioxidant coating protection

3 , circuit board type (corner) coating

4 , ground wire , flying wire , coil fixed

5 , wave soldering through hole mask

Medical device UVLED light curing application

UV glue bonding makes economical automated assembly of medical devices easier. Nowadays , the advanced LED UV light source system , which can cure solvent-free UV glue for a few seconds , as well as the dispensing system , makes an effective and economical method for consistent and repetitive bonding of medical device assembly processes. The optimization and control of UV light sources is very important for the manufacture of reliable medical devices. The use of UV-curable glue offers many advantages , such as lower energy requirements , saving cure time and location , increasing productivity and making automation easier. UV glue is commonly used to bond and seal medical devices that require very high quality and best reliability. UV glue curing Typical applications are in the medical device assembly , such as the need bond 1) of different material ( or different mechanical properties ) 2) material is not thick enough , can not use the soldering method 3 ) pre-production of sub-parts. .

1 , anesthesia mask 2 , syringe 3 , catheter 4 , intravenous infusion tube 5 , vascular implant accessories 6 . Endoscope 7 , arterial positioning 8 , tubular drainage device 9 , tracheal tube 10 , blood oxygenator 11 , hearing aid 12 , detection , monitoring , and imaging equipment 13 , biochip 14 , bonding PVC, thermoplastic ( polycarbonate) Fat and ABS)

Optical Industry - ST-UVLED Light Curing Applications

1. Optical component assembly (lens group , prism , optical engine assembly)

2. Image instrument assembly (microscope , endoscope , infrared , night vision , probe, etc.)

Optical communication industry UVLED light curing application

1.Passive components (wavelength division multiplexer WDM, array grating waveguide AWG, optical splitter SPLITTER, optical isolatorISOLATOR, optical coupler COUPLOR, etc.) , various glass package structure bonding or potting , fixing of small components Wait.

2.Active devices (coaxial devices TOSA/ROSA/BOSA, VCSEL , laser collimators, etc.), especially FTTX low-cost miniaturized plastic package structures

3. Fiber optic cable (overcoat , marking , bonding, fiber optic gyroscope)

Research and Institute - ST-UVLED Light Curing Application

1. Polymer chemistry ( nano coating , photocurable resin , photosensitizer , monomer , UV ink, etc. )

2 , medical polymer materials ( medical plastics , catheters ), microorganisms

3 , photochemistry ( photocatalysis , photoexcitation , photosynthesis, etc. )

4 , semiconductor ( light accelerated etching , cutting , uv tape, etc. )

other apps

1. UV analyzer, biological genetic engineering, molecular genetics, medical hygiene, biological products, pharmaceutical research, health and epidemic prevention, dye chemical, petrochemical, textile industry, public security and political law department, cultural relics and archaeological department, where fluorescence analysis is required. The department can use it.

2 , biochemistry , microbiology , genetics , genetics , medicine , catalysis, each channel uses different wavelengths of ultraviolet LED ,from 240nm to 410nm , every 5nm step, for detailed analysis

3 , ultraviolet light therapy, medical applications, such as: dental curing, vitiligo treatment, wound complex promotion.

4 , standard light source, because LED light spectrum is relatively single, energy is consistent, can be used as an effective standard light source

5 , criminal investigation light source, with high-power LED , can emit a uniform intensity of light from 365nm to 780nm , from ultraviolet, purple, blue, green, blue, yellow, orange, red, to the infrared band, can provide 12 bands The light and includes a white light.

FPC surface protection adhesive curing, 150mm UV LED Curing Machine features:

1 : cold light source, no heat radiation, especially suitable for liquid crystal edge sealing, film printing requires a small temperature rise area for use.

2 : Instantly illuminate, instantly achieve 100% power UV output, and the irradiation intensity can reach 8000-9000mW/cm2.

3 : Small size - makes the equipment easy to integrate into fully automatic production lines and equipment.

4 : It does not use toxic substances and does not produce ozone. It is a safer and more environmentally friendly alternative to traditional light sources.