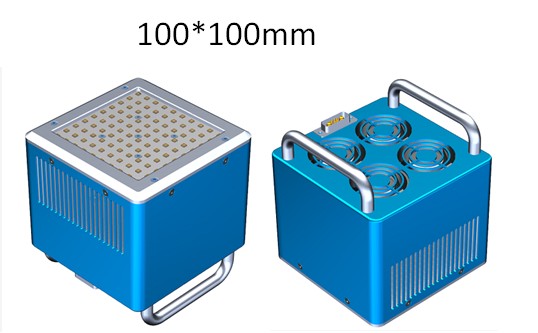

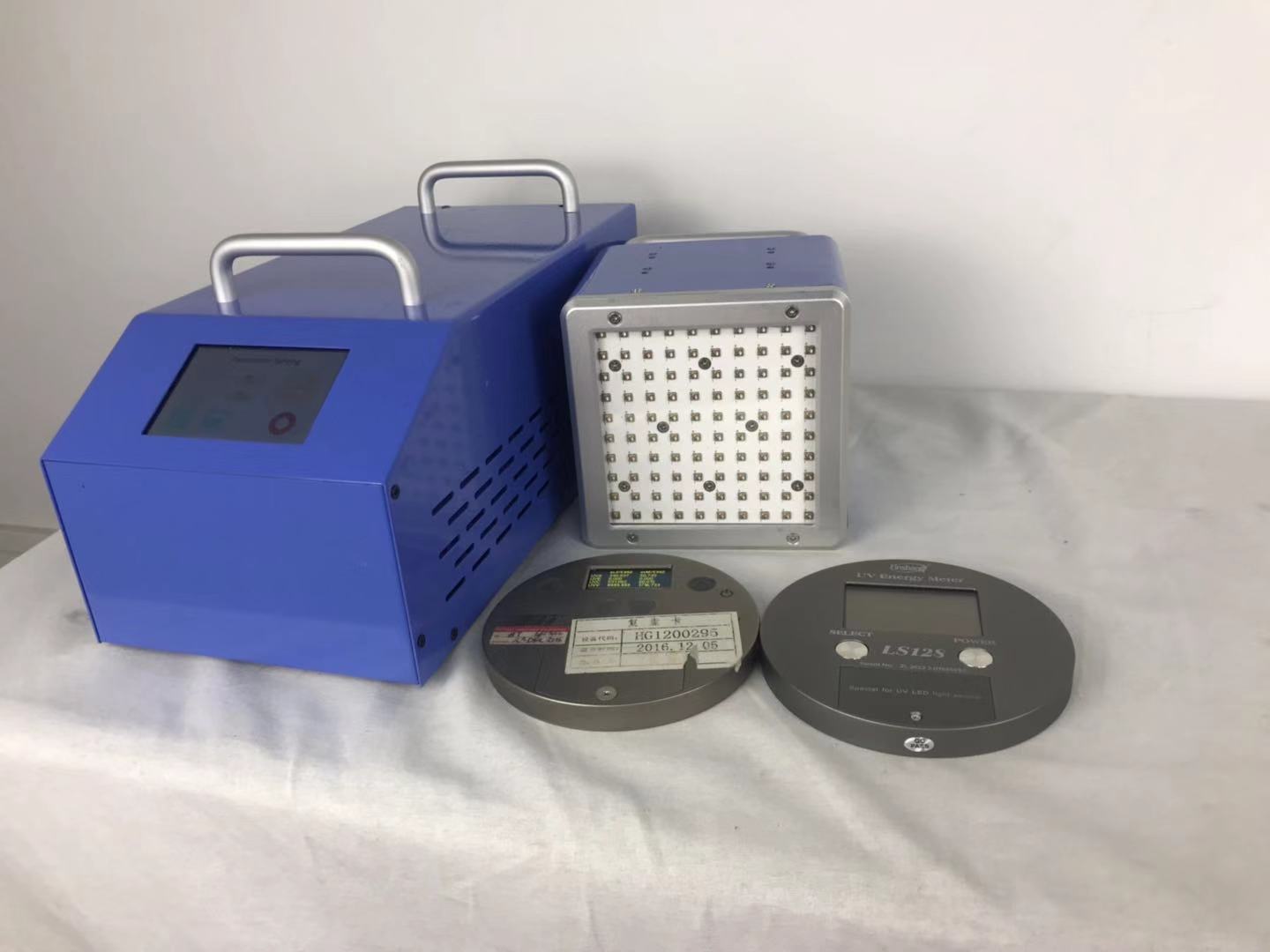

Factory Direct Sales, 100*100mm UV LED Surface Light Source uses Korean original factory imported UV LED UV Light Beads, curing UV glue and UV ink, quality guranteed.

Controller specification of Rectangular Irradiation Head UV Curing Machine :

shape

|

L320*W130*H130mm

|

weight

|

2.7kg

|

cool down

|

Air cooled

|

Input power

|

100-240V AC 50-60 HZ

|

material

|

Blue paint

|

Number of driving heads

|

One

|

RS232 serial communication

|

Can query and adjust intensity, time, mode

|

Display and operation

|

Touch screen for adjustable time and intensity

|

LED time accumulation

|

Active record cumulative usage time

|

External terminal block

|

Can be connected with single-chip, PLC and other equipment for control and working status feedback

|

Glow head specifications of 100*100mm 405nm UV Light Source :

Light size

|

100 * 100mm

|

power

|

300W

| |

Dimensions

|

L 130*W130*H112 mm

|

Recommended height

|

5 mm

| |

cool down

|

Air cooled

|

wavelength

|

365 / 385 / 395 / 405

| |

Material / weight

|

Sheet metal / 2kg

|

Luminous power (mW/cm 2 )

|

1800

|

2000 @ EIT

|

Prediction of service life

|

20000 H

| |||

Monitoring method

|

temperature check

|

Cable length

|

2 / 5 m

| |

100*100mm UV LED curing machine long-term stock inventory, can be shipped the same day. For other sizes of UV Machine, please contact customer service or directly contact Jennifer : +86-18924372460.

UV Light Source product advantages :

Single wavelength UV output with no harmful thermal effects

The high-power LED radiation single-wavelength light source is highly targeted and efficient. Eliminates the effects of source radiation other than the dominant wavelength. In particular, it does not contain infrared rays, which greatly reduces the thermal impact on the workpiece. It is the ideal source for high-precision curing that is very sensitive to thermal effects. For example, the assembly of an ultra-thin resin lens.

Low power consumption, saving energy

A low power consumption equivalent to only a few tenths of a UV mercury lamp is achieved. Products can significantly reduce energy consumption and waste emissions every year. Reduce environmental load.

Free layout and space saving

With UV-LED, the volume is reduced by about 90% compared to the UV mercury lamp. The weight is also greatly reduced, no need to worry about the installation space, and the layout is more free.

The head can be controlled separately or at the same time, saving equipment investment

According to the need to select the number of illumination heads, multiple conventional UV mercury light sources can now be replaced by a UVLED line or a surface light source. Reduce equipment investment, while the head can be controlled individually or in conjunction according to on-site process requirements.

Stable output accuracy

The unique heat dissipation technology in the UV-LED field creates a cooling method that combines high light quantity and long life to minimize drift and achieve stable illumination.

Long life and reduced operating costs

Compared with UV mercury lamps, the life of LED lamps is greatly extended. This is the characteristic of LED. Unlike UV mercury lamps, which can only be brightly lit, UVLEDs can be turned off instantly, so the actual life span is even greater.

Wide range of uniform illumination

With a unique optical system, UV illumination that minimizes variations in light amount over a wide range is achieved. It can inhibit curing and drying spots and curing deformation of adhesives, and assist customers in quality management.

The installation dimensions in the figure below are detailed in the specifications at the time of shipment.The shipping date shall prevail.

Detailed application areas UVLED surface light source 100*100mm is used in the following industries.

No comments:

Post a Comment