In the semiconductor chip production process, the wafer shall be fixed on the frame with the wafer film before the chip scribing. After the scribing process is completed, LED UV light is used to illuminate the fixed film to make the UV film viscous curing and hardening, so as to reduce the viscosity of the scribing fixed film and facilitate the smooth production of the subsequent packaging process. In other words, UV tape has a strong adhesive strength that will hold the wafer firmly during the wafer grinding or cutting process. When the ultraviolet radiation, the bonding strength becomes low. As a result, the wafer or chip can easily peel off the adhesive tape after being exposed to ultraviolet light. UV Wafer Tape Curing System solves the curing process of wafer, glass and ceramic cutting technology, which is not only limited to semiconductor packaging industry, but also applicable to UV film curing of optical lens, LED, IC, semiconductor, integrated circuit board, mobile hard disk and other semiconductor materials. UV mercury lamp is commonly used in existing UV curing machines, but the mercury lamp light source with high heat emission is easy to damage thermal sensitive materials, with low efficiency and difficult to accurately control the quality standard, which is not suitable for the irradiation of high precision devices such as chips. The environmentally friendly low temperature LED UV light source curing machine adopted by Guangdong SpaceLight Technology Co., Ltd. can easily finish the UV film curing process without damaging the wafer, which can greatly meet the production requirements.

Parameters of Large UV LED Exposure Machine :

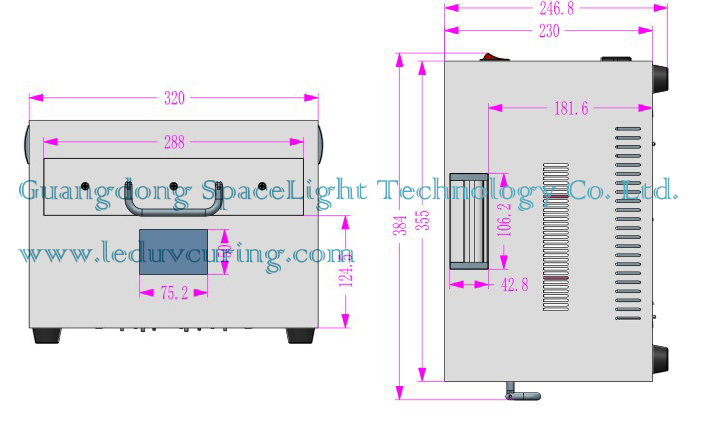

Host Size of UV Curing Light Chamber

|

L320*W384*H246.8mm

|

Weight

|

6.5kg

|

Cooling

|

Air cooling

|

Input Power

|

100-240V AC 50-60 HZ

|

Material

|

White sheet metal

|

Drive the Number of Luminous Heads

|

A light source

|

Craft

|

Stoving varnish

|

Display and Operation

|

Touch screen display, adjustable time, illumination

|

Set the Lock

|

Changeable password

|

LED Time Accumulation Function

|

Actively record cumulative usage time

|

Luminous Dimension of UV LED Exposure Equipment

|

Diameter : 150mm

|

Total Power

|

350W

|

Fixture Size

|

5.9 inch

|

Recommend highly

|

10~15mm

|

Cooling

|

Air cooling

|

Wavelength

|

Default 365nm, customizable 385 / 395 / 405

|

Illuminance

|

300-2000mW/cm2

|

Light Source Predicts Service Life

|

20000 H

|

Characteristics of Semiconductor UV Tape Curing Machine :

1.Small body, suitable for 6/8/12/15 inch chip irradiation.

2.Time and brightness adjustable, touch screen operation, simple and convenient.

3.Bottom up irradiation for easy placement of wafers.

4.LED clod light source, environmental protection products, with low temperature, uniform exposure, compact structure, low energy consumption, is the ideal type of semiconductor industry, and low temperature no damage to thermal sensitive materials.

5.Its service life is 10 times longer than that of ordinary mercury lamp. Its continuous service life is 15000-30000h.

6.Zero maintenance cost, long-term work without replacement of lighting source parts.

7.Enclosed light source design, no ultraviolet side leakage, no damage to human body.

No.

|

Content

|

Parameters

|

1

|

Wafer size

|

6” 8”10” 12‘’ (multiple specifications are available)

|

2

|

Light area

|

Φ150mm, Φ200mm, Φ300mm

|

3

|

Nominal voltage

|

AC 110/220V

|

4

|

Frequency

|

50/60HZ

|

5

|

Rated power

|

350-900W

|

6

|

Wavelength of UV Light

|

365nm-415nm selectable, normal 365nm

|

7

|

Dimension (L*W*H)

|

320mm×384mm×247mm

(size customizable)

|

8

|

Machine weight

|

6.5kg

|

9

|

Film type

|

UV film all kinds of UV Tape

|

10

|

Thickness of the film

|

0.15~2mm

|

11

|

Irradiation direction

|

Bottom up exposure

|

12

|

Operating mode

|

Touch screen operation

|

13

|

Timer setting time

|

Unlimited, adjustable (unit : s)

|

14

|

Completion time of curing

|

Depending on UV tape characteristics (minimum 5s)

|

15

|

Exposure intensity setting

|

20% ~ 100%, adjustable brightness

|

16

|

System fittings

|

Customized according to customer requirements. Default 5.9 inch.

|

No comments:

Post a Comment