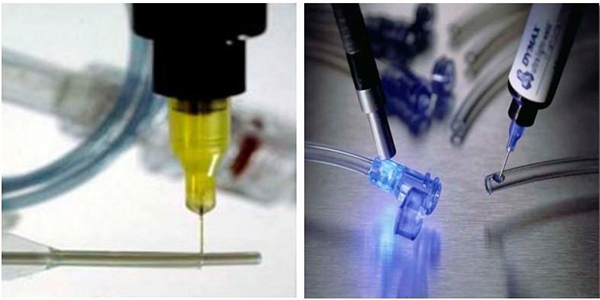

UV glue bonding makes economic automatic assemble of medical instruments easier. Now, advanced LED UV Curing Light Source can solidify solvent-free UV glue in seconds, and the dispensing system is an effective and economical way to form a consistent and repeatable adhesive during the assembly process of the medical devices. The optimization and control of Spot LED UV Solidification light source is very important for the manufacture of reliable medical devices. Using UV curing glue provides many advantages, such as lower energy requirements, saving curing time and location, improved productivity, and easier automation. UV glue is generally used to bond and seal medical instruments, these medical instruments need very high quality and the best reliability. UV glue curing is typically used in medical device assembly where bonding is required, 1) to different materials (or mechanical properties are different), 2) the materials are not thick enough to use the soldering method, 3) pre-produce sub-parts.

App 1 : fast curing UV adhesive for bonding glass and metal

App 2 : quick curing UV three-resistant paint on the circuit board

App 3 : fast curing UV ink printed on the shirt

App 4 : instantly curing UV glue for bonding disposable medical catheters, containers or other medical equipment

App 5 : instantly solidify the colored UV ink on the plastic mobile phone case

App 6 : instant curing bonding between the electronic paper book display surface and the protective film UV water glue

App 7 : instant solidify and bond all kinds of crystal, glass and other handicrafts, commemorative plaque, key chain UV glue, as well as UV varnish on wood surface

App 8 : instant curing UV adhesive for bonding all kinds of LCD glass and its gold pins, as well as curing UV sealant for the end of LCD

App 9 : instant uniform curing UV adhesive bonding all kinds of touch screen and screen protective film

No comments:

Post a Comment