Correct Storage Method of Ultraviolet LED Lamp / UV LED Correct Storage Method

Conditions | Temperature | Humidity | Time | |

Storage | Before opening aluminum bag | ≤30℃ | ≤90%RH | Within 1 year from delivery date |

After opening aluminum bag | ≤30℃ | ≤70%RH | 168hours | |

Baking | 65±5℃ | - | 24hours | |

1.The storage/packaging requirements for this LED are comparable to JEDEC Moisture Sensitivity Level (MSL) 3 or equivalent. NCHIA used IPS/JEDEC STD-020 as a reference to rate the MSL of this LED.

2.This LED uses a package that could absorb moisture. If the package absorbs moisture and is exposed to heat during soldering, it may cause the moisture to vaporize and the package to expand and the resulting pressure may cause internal delamination. This may cause the optical characteristics to degrade. To minimize moisture absorption in storage/transit, moisture-proof aluminum bags are used for the LEDs with a silica gel packet to absorb any air moisture in the bag. The silica gel beads turn blue to red as they absorb moisture.

3.Once the moisture-proof aluminum bag is open, ensure that the NICHIA Ultraviolet LED is soldered to a PCB within the range of the conditions above. To store any remaining unused LEDs, use a hermetically sealed container with silica gel desiccants. NICHIA recommends placing them back to the original moisture-proof bag and reseal it.

4.If the “After Opening” storage time has been exceeded or any pink silica gel beads are found, ensure that the LED are baked before use. Baking should only be done once.

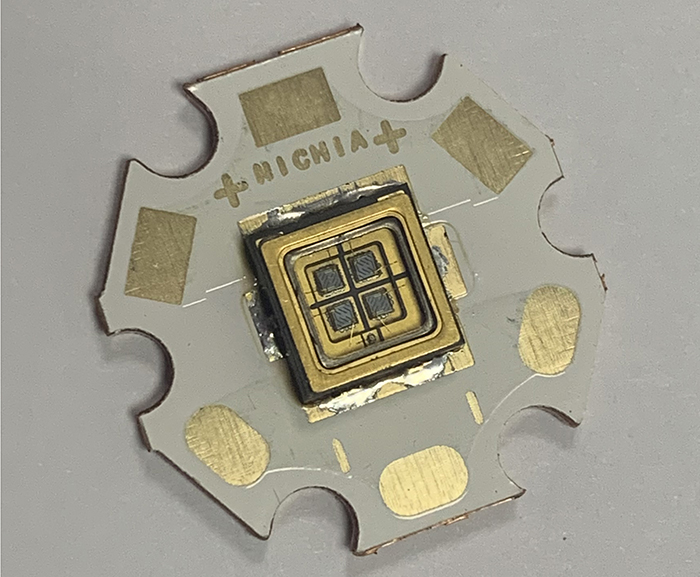

5.This LED has gold-plated electrodes. If the LEDs are exposed to a corrosive environment, it may cause the plated surface to tarnish causing issues (i.e. solderability). Ensure that when storing LEDs, a hermetically sealed container is used. NICHIA recommends placing them back to the original moisture-proof bag and reseal it.

6.To prevent substance/gases from affecting the plated surface, ensure that the parts/materials used with the SMD UV LED Lamp Chips in the same assembly/system do not contain sulfur (e.g. gasket/seal, adhesive, etc.). If the plating is contaminated, it may cause issues (e.g. electric connection failures). If a gasket/seal is used, silicone rubber gaskets/seals are recommended. Ensure that this use of silicone does not result in issues (e.g. electrical connection failures) caused by low molecular weight volatile siloxane.

7.To avoid condensation, the LEDs must not be stored in areas where temperature and humidity fluctuate greatly.

8.Do not store the UV Light Emitting Diode Chips in a dusty environment.

9.Do not expose the LEDs to direct sunlight and/or environment over a long period of time where the temperature is higher than normal room temperature.

No comments:

Post a Comment