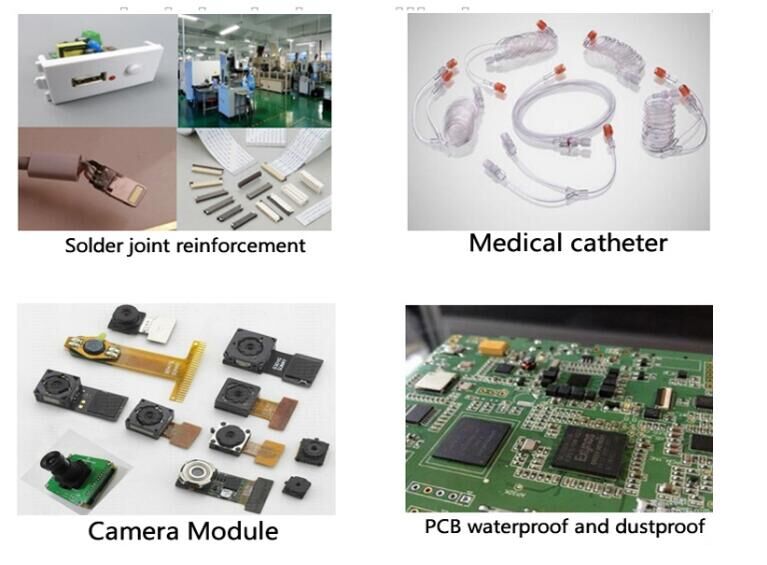

100X100mm LED UV Curing Equipment is a high performance UVLED surface light source curing system designed for UV adhesive curing. The system mainly includes control system, UVLED head and conveyor belt. The UVLED head of the machine is integrated with imported high-intensity UV LED. The UV spectrum wavelength is 365nm. The effective curing area is 100X100mm, which supports external signal input and triggering. It can be used in semi-automatic or fully automatic production lines. The conveyor belt is made of Teflon.

Specification Sheet

wavelength: 365nm

Model: DSX-S256-100X100-365

Electric power: 768W

Optical power density: 3500MW/CM2

Irradiation area: 100X100mm

Irradiation height: 10mm

Cooling method: Air cooled

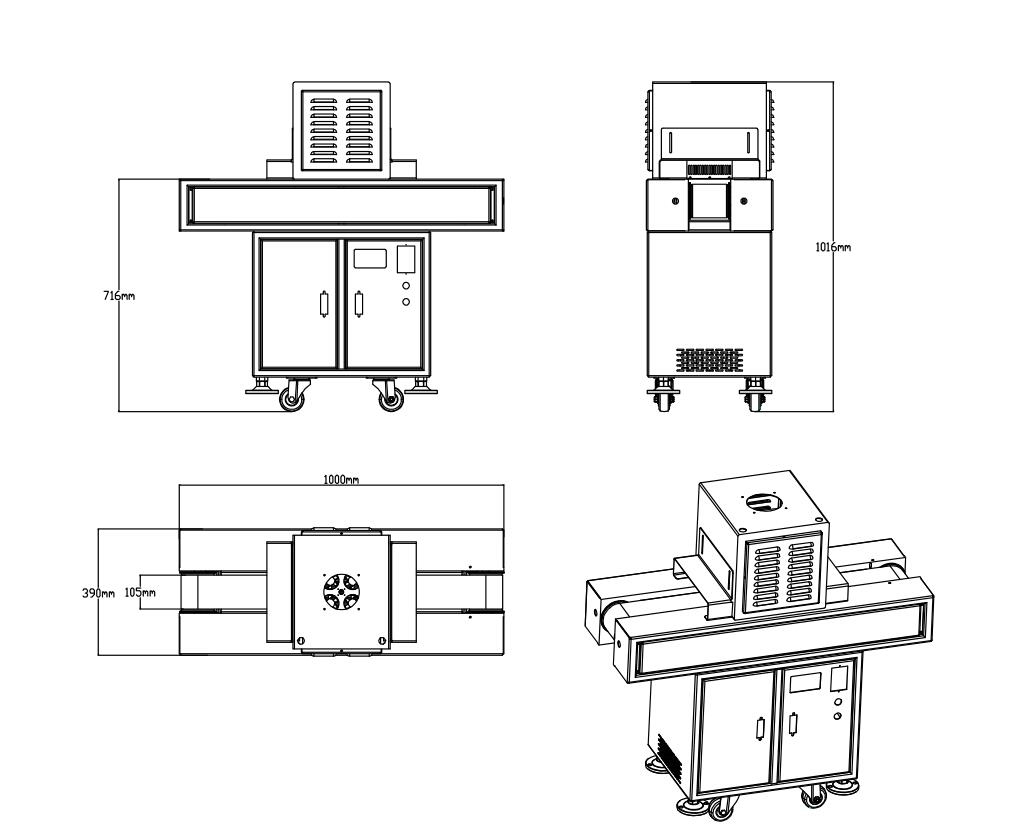

Overall size: L1000mm*W390mm*H1016mm

Product Overview

LEDUV curing machine replaces traditional mercury lamp, built-in UVLED curing light source, low temperature, no ozone, no deep ultraviolet, low energy consumption, high efficiency, no infrared radiation, cold light source, suitable for curing of various heat sensitive materials UV glue, infrared transmission Intelligent control, start-stop control on demand.

Advantage :

1. Instant drying: avoid waiting for drying time, greatly shorten the time of coating process.

2. Directly with the coating machine manufacturer: can connect the roller type or the curtain coating machine, the finished product is directly dry after the coating, avoid the transportation trouble.

3. The surface hardness of the coating is improved and the color is bright.

4. Extensive drying function: wood, board, furniture, steel plate, building materials, lens, leather and other UV coating after coating drying.

5. Fast curing speed, high production efficiency, the curing mechanism is a kind of free radical chain reaction, the cross linking solidification in an instant.

Application :

No comments:

Post a Comment