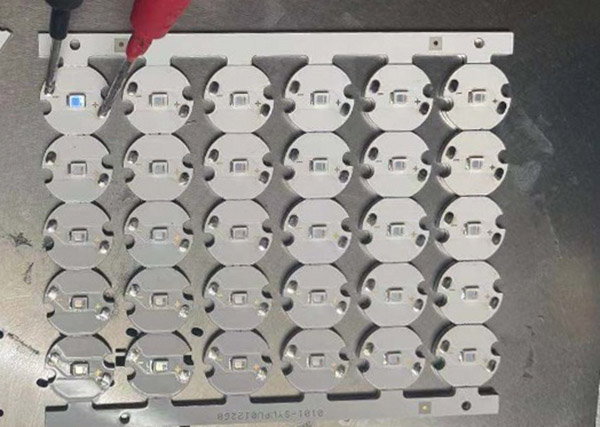

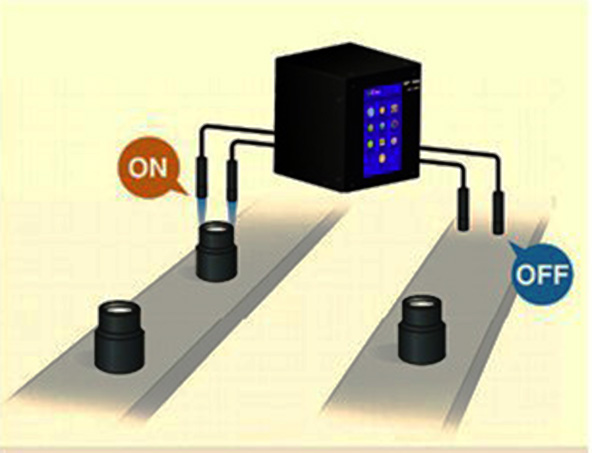

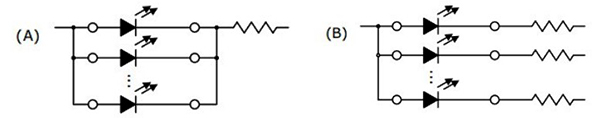

Because LED is a constant current driven electronic component, it is known from the characteristic curve of LED I-V that when the voltage changes slightly, the current passing through the LED will change greatly, which may cause the uneven current flowing into LED. Therefore, LED circuit design is not allowed to use the constant voltage way to drive. If the constant voltage drive is unavoidable, it is best to use the following (B) circuit. Because the difference in the positive voltage of each LED in the (A) circuit may cause the current flowing into the Ultraviolet LED Lamp Chips to be uneven. In addition, it is necessary to measure whether the current through the LEDs is within the working current range of the standard specifications during product design and trial production.

1.Please use forward current to drive Ultraviolet Light Emitting Diode. Do not apply voltage to the product in the positive or negative direction when the product is not in use. In particular, do not apply voltage to the product continuously in the negative direction. This may lead to ion migration and damage to the LED. If the product is not used for a long time, in case of emergency, the main power supply should be turned off.

2.Because the test current of LED with different power will be inconsistent, it is necessary to read the product specification in detail when using Ultraviolet LED, and it is advisable to use the standard not exceeding the scope of specification identification. Because LED is an electronic component, the internal resistance of LED is caused by the change of ambient temperature. Therefore, the specifications and parameters of our company’s related products are tested under the condition of 25 ℃ at room temperature.

3.(i.e. AC to DC product). In the current conversion process, there may be a pulse signal, high voltage pulse signal will cause damage to the UV LED P/N junction, resulting in the LED failure. Therefore, the voltage fluctuation we allow is within 2%.

4.When test power supply is used for spot measurement and inspection of semi-finished products, the no-load voltage of the test power supply should be paid attention to. In general, the no-load voltage is required to be lower than actual demand voltage of the load, so as not to damage the UV LED Light Beads due to the high no-load voltage of the power supply and any over-voltage of the load at the moment of point measurement.

5.Different voltage products can not be applied to the same parallel circuit, which will increase the LED voltage drop difference and lead to a large difference in the current passing through a single LED, which will affect the radiation flux and reliability of Ultraviolet LED Light Chips, and will cause burnout and failure in serious cases.

(Note: current limiting measures are necessary, otherwise a slight voltage change will cause a large current change, which may cause LED failure.)