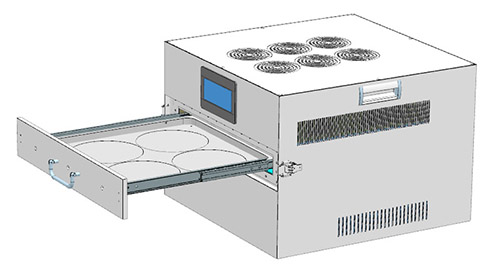

Nitrogen UV LED Curing Machine is also a system engineering, integrated with nitrogen protection system, but also integrated with other UV Irradiation Systems of the main body, such as the UV LED light module, drive control, air cooling system and other parts. Because of its higher technology, it is more difficult to manufacture. But compared with the original Wafer-Bonding UV Curing Machine, the LED UV Light Curing Equipment with Nitrogen protection will be better in the ungluing efficiency. The main reason is that the original Wafer-Bonding UV Curing Machine exists in the air between the luminous source and the irradiated object, the oxygen contained in the air will have dust. And when the UV emits ultraviolet light, water vapor and oxygen will be produced between the emitting body and irradiated object, which will reduce the energy of ultraviolet light and thus reduce the UV degumming effect. However, with nitrogen protection, the air is completely isolated so that there is no air between the light source and the object to be cured. So the efficiency of curing effect will be higher and more thorough.

Nitrogen (N2) is a kind of inert gas, is a protective gas, so it is called “nitrogen protection”. Nitrogen is chemically inert. Its molecules are larger than those of oxygen. It is usually a colorless, odorless gas and is generally less dense than air. Nitrogen, which accounts for 78.12% (volume fraction) of the total atmosphere, is the major component of air. Nitrogen reacts poorly with other substances at room temperature. Nitrogen is not easy to expand and contract in heat and cold, and its deformation range is small. Based on nitrogen’s various chemical properties and mechanical properties are better than air, Shenzhen Deshengxing Electronics Co., Ltd. studies the use of nitrogen filled LED UV Light Curing Equipment to discharge oxygen. Shenzhen Deshengxing Electronics Co., Ltd. research of the nitrogen protection in the glue machine refers to the establishment of a relatively closed space in the LED UV Light Curing Machine, the use of nitrogen N2 filled into it, thus greatly reducing the oxygen in the air and water vapor on the UV light source polymerization reaction. Because oxygen and water vapor will be involved in UV LED chemical reaction, loss of UV energy, ozone and affect the chemical reaction of photosensitizer.

The “nitrogen protection system” greatly improves the efficiency of UV degumming and thus greatly improves a series of problems inherent in UV Irradiation Systems of traditional mercury lamp sources. In addition, the speed and uniformity of degumming process are also improved, that is, more kinds of UV films can be degumming without worrying about the effect of degumming.

No comments:

Post a Comment