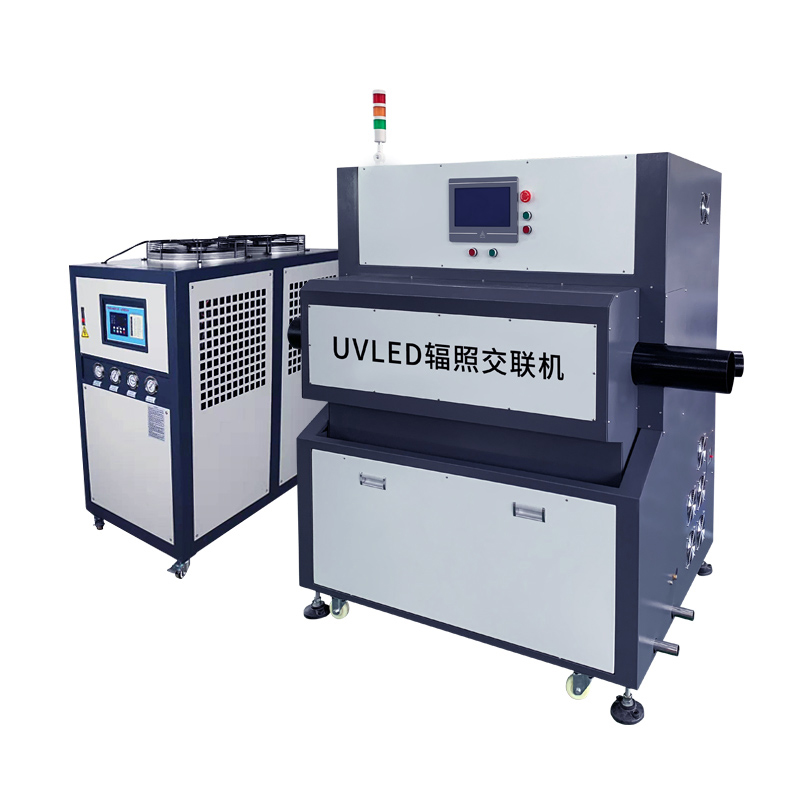

The advantages of Cable UV Light Irradiation Crosslinking Machine are mainly reflected in: low energy consumption, short time, low cost, small size, easy installation and operation, long life, low maintenance cost, no ozone, green environmental protection.

Why? Please browse the following articles.

1.Low energy consumption

The installed power of the UVLED Type Ultraviolet LED Polyolefin Crosslinking Equipment is equivalent to 1/4 of the original ultraviolet irradiation equipment, 1/30 of the electron accelerator, water or steam needs to be heated for a long time, and the energy consumption of heating is very high.

2.Fast production

The cross-linking uses online extrusion cross-link to reduce the subsequent cross-linking process. Compared with the time required for boiling or steam-assisted silane cross-linking and entrusted electron beam irradiation processing, it saves wire and cable manufacturing time, especially emergency task completion has obvious advantages.

3.Low production cost

Compared with warm water cross-linking and entrusted electron beam irradiation process, the price of UV-irradiated cables is low, and many complicated processes are reduced during the production process, such as the transportation cost of semi-finished cables and the corresponding operator costs.

4.Small in size, easy to installation

Just add a distance of about 2m between the extruder die of the original production line and the warm water tank, and place the irradiator in a space with a width of 2.5-3 meters.

5.Easy to operate

Pneumatic reversal to open the tunnel structure, easy to clean and thread through, simple operation, no complicated process, can be completed by the extruder operator.

6.Long life expectancy of the system, low cost of maintenance

The life of LED devices is about 30000 hours, and the life of other electrical and electronic devices is not less than life general electrical and electronic products, without frequent maintenance. Regular maintenance is to keep the optical lens clean. The consumables are industrial wipes and fume cleaner, which can be done by the operator.

7.Harmful emission radiation and pollution environment friendly

Very high wavelength selectivity, only emit useful wavelengths, no infrared radiation, low calorific value. Very low amount of visible radiation, no light pollution, no short wavelength ultraviolet radiation, no harm to human body, zero ozone emission. Only need to connect a small diameter smoke exhaust pipe and a 2KW fan to remove the low molecular smoke produced when the insulation is extruded to prevent affecting the effect of light irradiation.

8.Environment friendly

“Industrial Hygiene Standards” stipulates that ozone safety standard is 0.15ppm, the ambient air quality standard (GB3095-2012), UV LED ultraviolet Light Cross-Linking Equipment will not produce ozone, and traditional mercury lamp equipment will produce a large amount of ozone, ozone belongs harmful gas.

No comments:

Post a Comment