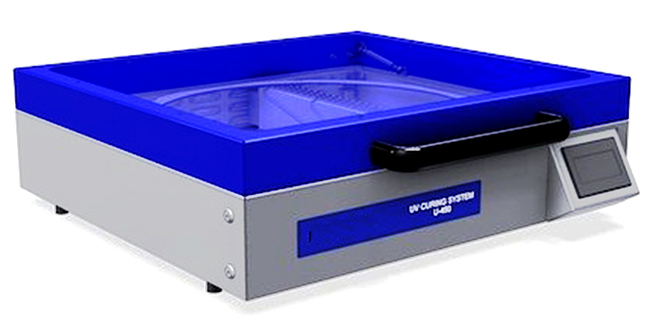

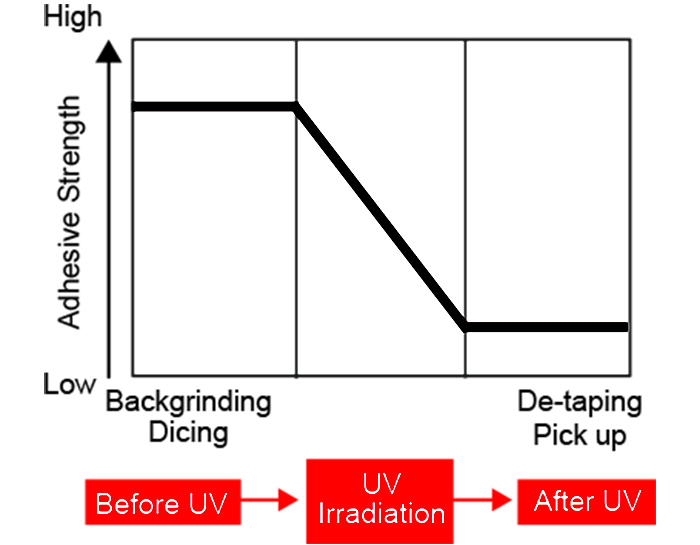

Opening the cover and inserting the wafer to the glass pane, then closing the lid, the UV LED Exposure Machine will start immediately. Curing is completed after about 10-60 seconds, yielding a consistent throughput of 50 to 180 wafers/hour. Fully adjustable exposure dose ranges between 80 mJ / cm2 to 1000 mJ / cm2.

There are numerous UV LED benefits such as less damage to the workpiece by exposure at ambient temperature, a very long lifetime, low power consumption, and safety for replacing the light source because it does not get hot compared to mercury lamps. Equipped with a high-output LED driver, we can achieve an exposure output over 600mW/cm2 (at 6.5mm work distance).

Feature of 6/8/12inch UV Light Curing Machine:

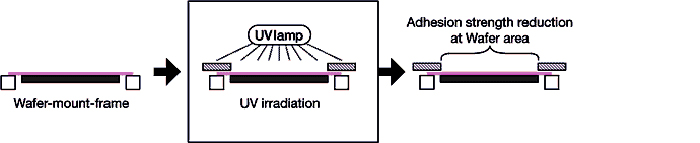

Homogeneous Debonding

Specifications of Silicon Wafer LED UV Curing Equipment :

Frame size: 6/8/12 inches

Types of film: UV film

Wafer: 12 inches and under

Radiation light source: LED UV light source, cold light source, 365nm

Intensity: 600-1000mW/cm2

Place the fixture: 6/8/12 inches wafer can switch with each other

Handling mode: manual put in and take out

Product fixed: alignment pin location

Electric power supply: 220V, 350W,8A

Volume: 645mm*620mm*195mm (L*W*H)

Net weight: 40-50KG

Performance of Dicing UV Flim Degumming Machine:

PLC + touch screen, software control

Irradiation time: 1-999s setting

Production capacity per hour: about 200pcs for general products

Pre-charge nitrogen setting

Key Features of Automatic LED UV Curing Systems :

Low costing procurement = Lowest total cost of ownership (COO)!

No development of harmful ozone

Zero warm-up time

Long service life of UV-LEDs (10,000hrs+)

Low intensity drop (5% in 10,000hours)

No thermal influence on the film

Compact and robust table design

Short installation and implementation time

Low maintenance costs

Conforms to IEC204-1 safety standards

Productivity 50-180 wafer / hr.

No comments:

Post a Comment