Product Details

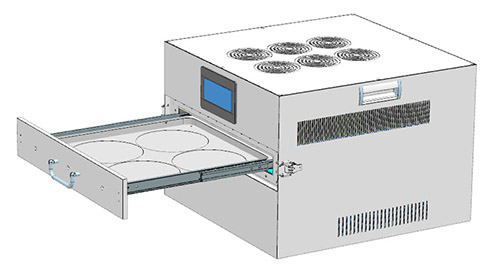

Automatic Nitrogen UV Curing Systems can curing 4 pieces 150mm diameter wafer. (the chip is coated with a film, which is placed upward).

Product Parameters :

Type | DSXUV-TapeCuring320X320 | Manufacturer | Shenzhen Deshengxing Electronics Co., Ltd. |

Outside dimension | L532.5*W5.2.91*H379.35mm | Compatible size | 320X320mm |

Cooling method | Air cooling | Input power | 100-240V AC 50-60HZ |

Total power | 1980W | Wavelength | UV LED 365nm |

Capacity of drawer | L368m* W348mm* H15mm | Intensity | >600mW/cm2 |

Material / weight | White sheet / naked machine 53kg | Display | Touch screen |

Function | Adjustable time and illumination | Irradiation direction | Top-down |

Operation :

1.Put it on the board and close the door

2.Automatic start of nitrogen filling

3.After being filled with nitrogen, the lamp will automatically turn on the light operating

4.After the automatic lamp is cured, the lamp is automatically turned off and nitrogen is simultaneously turned off

Please contact customer service for more customized requirements.

Application :

Suitable for optical lens, LED, IC, semiconductor, integrator circuit board, mobile hard disk, thermopile, sensors and other semiconductor materials, glass filter UV film curing, UV tape degumming use. UV Curing Machine is a kind of UV film and cutting film adhesive tape viscosity reduction and removal of automatic UV curing equipment. Wafer, glass and other materials, using UV Tape to glue on 6 / 8 / 12 /15 inches of bracket fixture curing dissolving device, with high efficiency of glue dissolving ability, can quickly reduce the adhesion of UV TAPE on materials.

Characteristics of Nitrogen UV Curing Machine :

1.Multiple wafers can be put into the machine at the same time

2.Adjustable operation time and brightness, touch screen operation, simple and convenient

3.The addition of nitrogen can exhaust other disturbing gases

4.LED cold light source, environmental protection products, with low low temperature, uniform exposure, compact structure, low energy consumption, is the ideal model of semiconductor industry, and low temperature to thermal-sensitive materials without damage

5.The service life is more than 10 times longer than that of ordinary mercury lamp. The continuous service life is 15000~30000 hours

6.Zero maintenance cost, no need to replace the light source parts for long-term work

No comments:

Post a Comment