Product Details

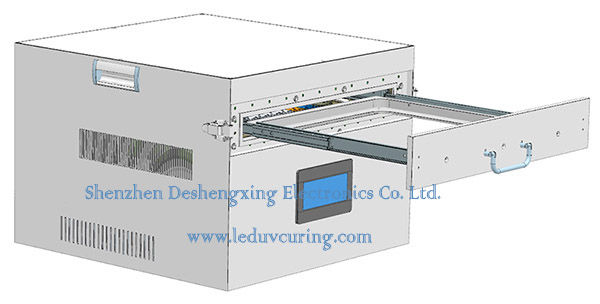

Automatic UV Wafer Tape Curing Systems are highly efficient and cost-effective semiconductor assembly equipment, high performance UV exposure uniformity and fast curing times.

Advanced circuitry and design with multiple features and options -- coupled with essentially zero downtime -- make DSXUV-N2-250250 Series an ideal choice for fast, uniform, and cost-effective UV LED curing requirements.

Product Parameters:

Outside dimension | L546.2*W519.63*H376.9mm | Compatible size | 250X250mm |

Cooling method | Air cooling | Input power | 100-240V AC 50-60HZ |

Total power | 1500W | Wavelength | UV LED 365nm |

Drawer capacity | L348mm * W368mm * H15mm | Intensity | >600mW/cm2 |

Material / Weight | White metal plate / naked machine 50kg | Display | Touch screen |

Function | Adjustable time and illumination | Irradiation direction | Bottom-up |

Operations:

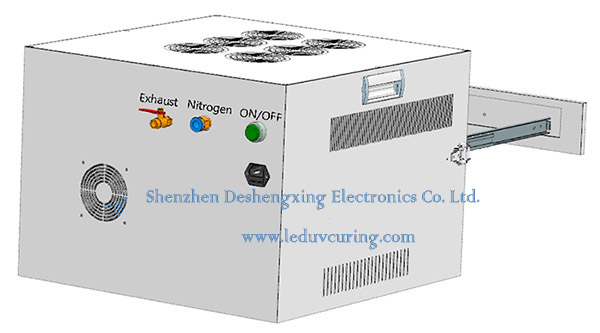

1.Put in the board and close the door

2.Automatically start filling with nitrogen

3.Automatically turn on the light and release the glue after being filled with nitrogen

4.Automatically turn on the light for curing, and turn off the nitrogen after debonding

Applications:

1. Suitable for optical lens, LED, IC, semiconductor, integrated circuit board, mobile hard disk, thermopile, sensors and other semiconductor materials, glass filter, etc., UV film debonding, UV tape break away from stuffs.

2. UV LED Tape Curing Machine is a kind of UV film and cutting film tape viscosity reduction and viscosity removal of automatic UV LED Curing Equipment.

3. Wafer, crystal round, glass and other materials, using UV tape adhesive for 6inch 8inch 12inch and 15inch of support to handle the glue device, has the efficient unglued ability, can quickly reduce the adhesion of UV tape on materials.

Characteristics :

1.High power UV LED, debonding speed is fast

2.Adjustable time and brightness, touch screen operation, simple and convenient.

3.The addition of nitrogen can exhaust other interfering gases

4.UV LED is cold light source, environmental protection products, with low temperature, uniform exposure, compact structure, low energy consumption, semiconductor industry is the ideal model, and low temperature to thermal-sensitive materials without damage.

5.The service life is more than 10 times longer than that of ordinary mercury lamp, with a continuous service life of 15000-30000h.

6.Zero maintenance cost, no need to replace the light source parts for long-term work.

7.Closed light source design, no ultraviolet side leakage, no damage to human body.

Features :

1. UV irradiation of 365nm wavelength

2. Manual loading, automatic UV process

3. Ideal for low volume and RnD applications

4. Compatible with size of 12’’ version and below

5. Frame or ring curing

6. Special box design to avoid UV leakage.

7. Automatic timing, warning device, easy to operate, high efficiency.

8. The device is heat-resistant and reinforced filter, which blocks the heat source and reduces the high temperature trouble.

9. Special heat sink to protect the lamp and extend the life of the lamp.

No comments:

Post a Comment