Features

● CMH real inorganic package

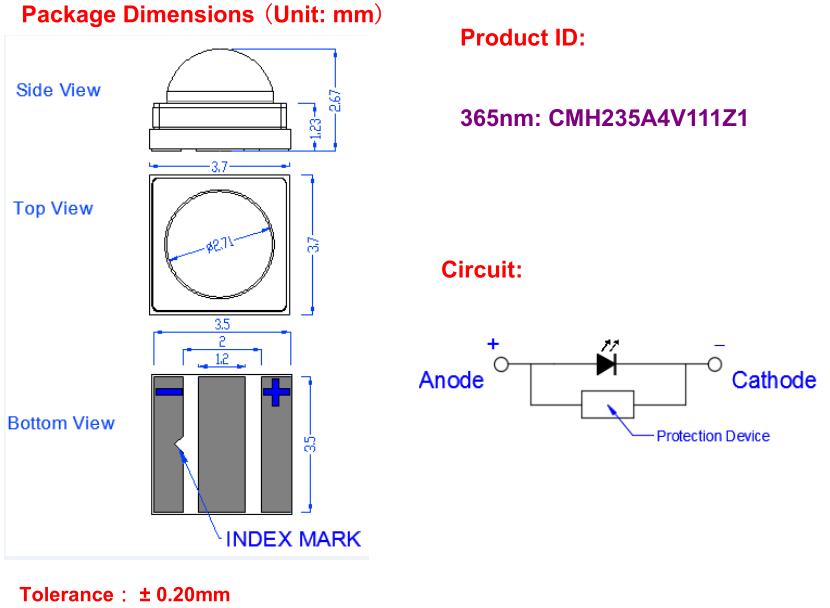

● Dimension 3.70mm×3.70mm×2.67mm

● Long operating life

● High reliability

● Superior ESD protection

● RoHS compliant

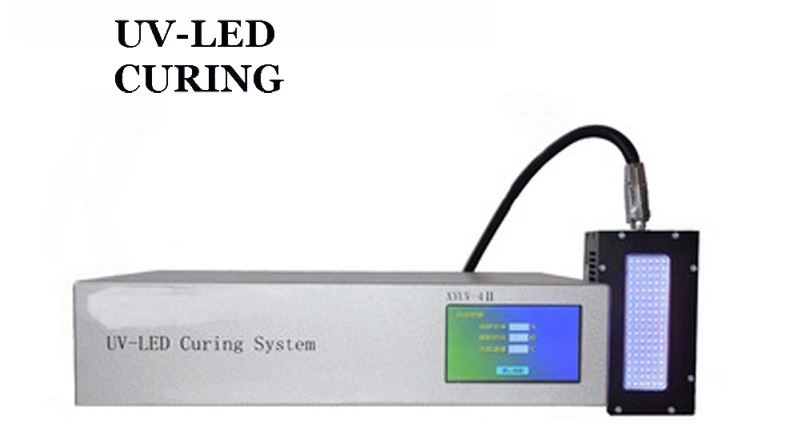

Applications

● Fluorescent spectroscopy

● Sensors and monitors

● Bio-analysis/detection

● Phototherapy

● UV curing

● Printing

● Coating

|

| https://www.leduvcuring.com/ |

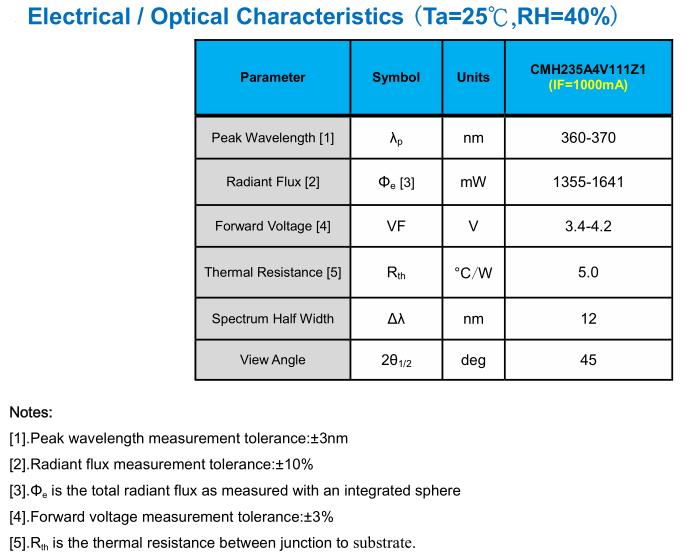

Characteristics of UV LED

Product Application Information

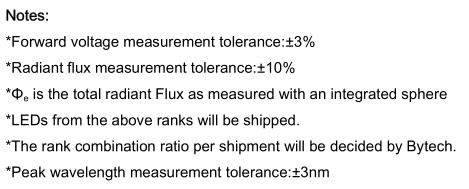

Notes:

*This LED is designed to be reflow soldered on to a PCB. If dip soldered or hand soldered, Bytech cannot guarantee its reliability.

*Reflow soldering must not be performed more than twice.

*Avoid rapid cooling. Ramp down the temperature gradually from the peak temperature.

*Nitrogen reflow soldering is recommended. Air flow soldering conditions can cause optical degradation, caused by heat and/or atmosphere.

*Since the glass used in the encapsulating glass is fragile, do not press on the hermetic glass. pressure can cause nicks, chip-outs, Sealant layer and deformation, and wire breaks, decreasing reliability

*Repairing should not be done after the LEDs have been soldered.

It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

*The Die Heat Sink should be soldered to customer PCB. If it is difficult or impossible, use high heat-dissipating adhesive.

*When soldering, do not apply stress to the LED while the LED is hot.

*When using a pick and place machine, choose an appropriate nozzle for this product.

*When flux is used, it should be a halogen free flux. Ensure that the manufacturing process is not designed in a manner

Where the flux will come in contact with the LEDs.

*Make sure that there are no issues with the type and amount of solder that is being used.

CAUTIONS

1. Handling Precautions

● Do not handle the LEDs with bare hands as it will contaminate the LEDs surface and may affect the optical characteristics.

● When handling the product with tweezers, be careful not to apply excessive force to the glass. Otherwise, the glass can be cut, chipped, delaminate or deformed, causing wire-bond breaks and catastrophic failures.

■ Dropping the product may cause damage.

2. Electrostatic Discharge (ESD)

● The product are sensitive to static electricity or surge voltage. ESD can damage a die and its reliability. When handling the products, the following measure against electrostatic dis-charge are strongly recommended: Eliminating wrist strap, ESD footwear, clothes, and floors Grounded workstation equipment and tools ESD table/shelf mat made of conductive materials

● Ensure that tools, jigs and machines that are being used are properly grounded and that proper grounding techniques are used in work areas. For devices/equipment that mount the LEDs, protection against surge voltages should also be used.

● The customer is advised to check if the LEDs are damage by ESD When performing the characteristics inspection of the LEDs in the application. Damage can be detected with a forward voltage measurement at low current(≤1mA).

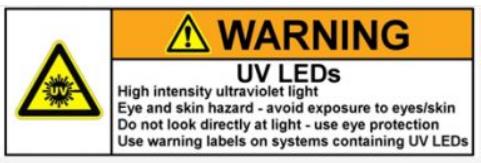

3. Eye Safety

● Please proceed with caution when handling any UV LEDs driven at low or high current. Since UV light can be harmful to eyes, do Not look directly into the UV light, even through an optical instrument.

● UV protective glasses are required to use in order to avoid damage by UV light in case of viewing UV light directly.