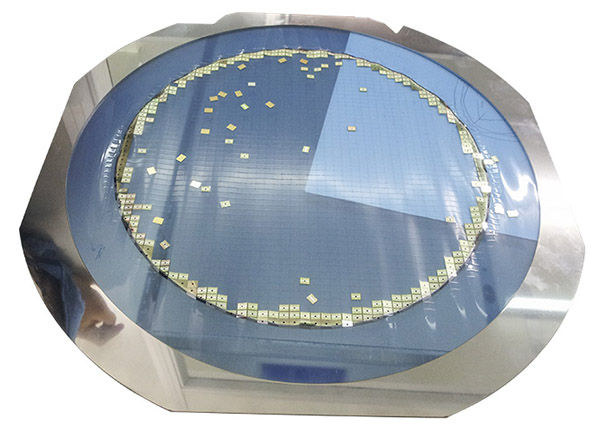

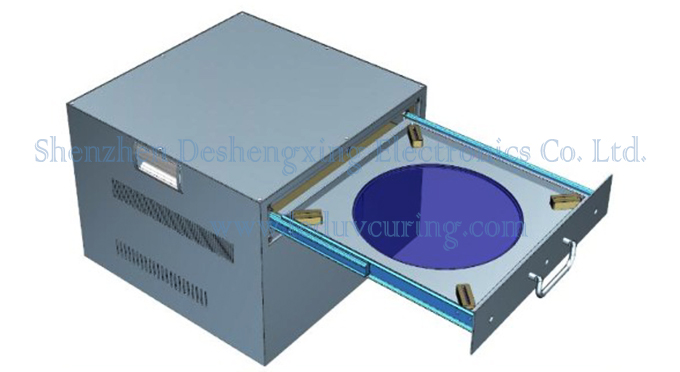

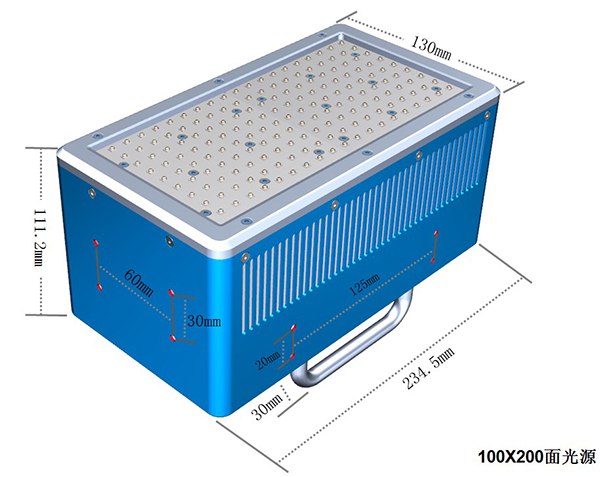

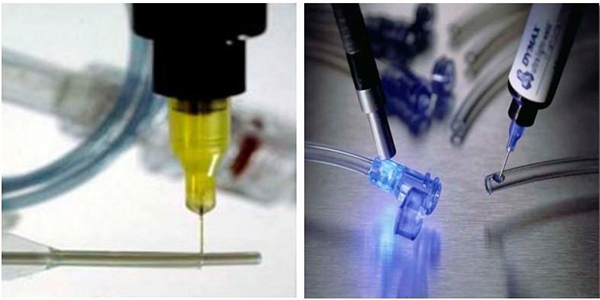

Before the chips scribing, the wafer is fixed to the frame with scribing film. After the scratching process is completed, UV light is used to irradiate the fixed film to make the UV film solidify and harder, so as to reduce the stickiness of the scratching fixed film and facilitate the smooth production of subsequent packaging processes. In other words, the UV tape has a strong adhesive strength and holds the wafer firmly during the wafer grinding process or the wafer cutting process. When ultraviolet LED light radiation, the bonding strength will be reduced. As a result, the wafer or chip can easily peel off the tape after UV LED Light exposure. UV LED Curing Systems Machine solves the degumming process of wafer, glass and ceramic cutting process. It is not only commonly used in semiconductor packaging industry, but also for the use of UV film degumming of semiconductor materials such as optical lens, LED, IC, semiconductor, integrated circuit board and mobile hard disk. The UV curing systems in the prior art mostly uses UV mercury lamp. The light source of UV mercury lamp with high heat emission is easy to be damaged by heat sensitive materials, and its efficiency is low, and its quality standard is difficult to be controlled accurately, so it is not suitable for high precision devices such as chips. Shenzhen Deshengxing Electronics Co., Ltd. adopts the environment-friendly low-temperature LED UV Curing Light Source Systems, easy to complete the UV film de-film process, and does not damage the wafer, greatly meet the production needs.

The details of "What is UV Film? UV Adhesive Principle"

Application :

Suitable for optical lens, LED, IC, semiconductor, integrated circuit board, mobile hard disk and other semiconductor materials, glass filter UV film degumming, UV tape degumming use. UV LED Curing Systems is a kind of UV film and cutting film tape viscosity reduction and viscosity removal of automatic curing equipment. The wafer, glass and other materials can be pasted on 6’’, 8’’ and 12’’ brackets with adhesive dissolving device, which has high efficiency of adhesive dissolving ability and can quickly reduce the stickiness of UV Tape on materials.