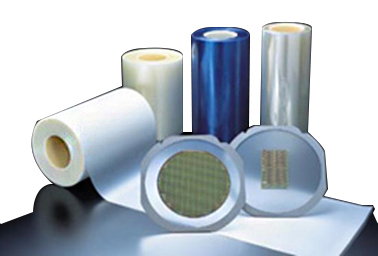

Both the UV tape and blue film are viscous, and their viscosity is expressed by the viscous peel degree, usually N/20 mm or N/25 mm. For example, the meaning of 1 N/20 mm is that the width of the test strip is 20 mm, and the force to peel it off from the test version with a 180° peel Angle is 1 N. UV film is a special formulation of coating on the surface of PET film substrate, to achieve the effect of blocking ultraviolet light and short-wavelength visible light. Figure 1 shows a general UV tape structure diagram. Generally, the UV tape is composed of 3 layers, the base material is polyethylene chloride, the viscous layer is in the middle, and the adjacent to the viscous layer is the Release film, some UV tape models do not have the coating.

UV tape is usually called ultraviolet radiation tape, the price is relatively high, and the validity period is short when not used. It is divided into high viscosity, medium viscosity and low viscosity. For the highly viscous UV tape, it is very viscous without ultraviolet irradiation, and the viscous peel degree is about 5 000 mN/20 mm to 12 000 mN/20 mm, but after the ultraviolet light irradiation time is extended and the irradiation intensity is increased, the peel viscosity will be reduced to less than 1 000 mN/20 mm. For the low-viscosity UV tape, without UV irradiation, its peel viscosity is about 1 000 mN/20 mm, and after ultraviolet irradiation, its peel viscosity will be reduced to about 100 mN/20 mm. The medium viscosity UV tape is between the high viscosity and the low viscosity.

After the low-viscosity UV tape passes a certain time and a certain intensity of ultraviolet irradiation, although its viscosity stripping degree will be reduced to about 100 mN/20 mm, there will be no residual glue phenomenon on the surface of the wafer, and the grains are easy to be removed. At the same time, the UV film has appropriate expansion, and in the process of thinning the scribing, water will not penetrate between the grain and the tape.

Blue film is usually called electronic grade film, the price is lower. It is a kind of blue viscosity unchanged film, relative to the high viscosity UV film that has not been irradiated by ultraviolet light, its viscosity stripping degree is generally low, not sensitive to ultraviolet light, the range is (1 000 ~ 3 000)mN/20 mm, and will produce residual glue affected by temperature. The first name is because the film is blue, and now with the development of technology, other colors have also appeared, and the use has been broadened. Compared with blue film, UV tape is more stable than blue film. UV tape whether before or after ultraviolet irradiation, the viscosity of UV tape is relatively stable, but the cost is high. The cost of blue film is relatively cheap, but the viscosity will change with the change of temperature, and it is easy to produce residual glue.