UV LED devices are the most advanced UV radiation sources in the world, characterized by extremely high energy efficiency (about 30%), extremely high selectivity of effective wavelength (half-power wavelength broadband: 5nm), extremely long service life (40,000 hours), low infrared heat and no ozone, making them more suitable for the cross-linking and solidity of cross-linked polyolefin and other materials.

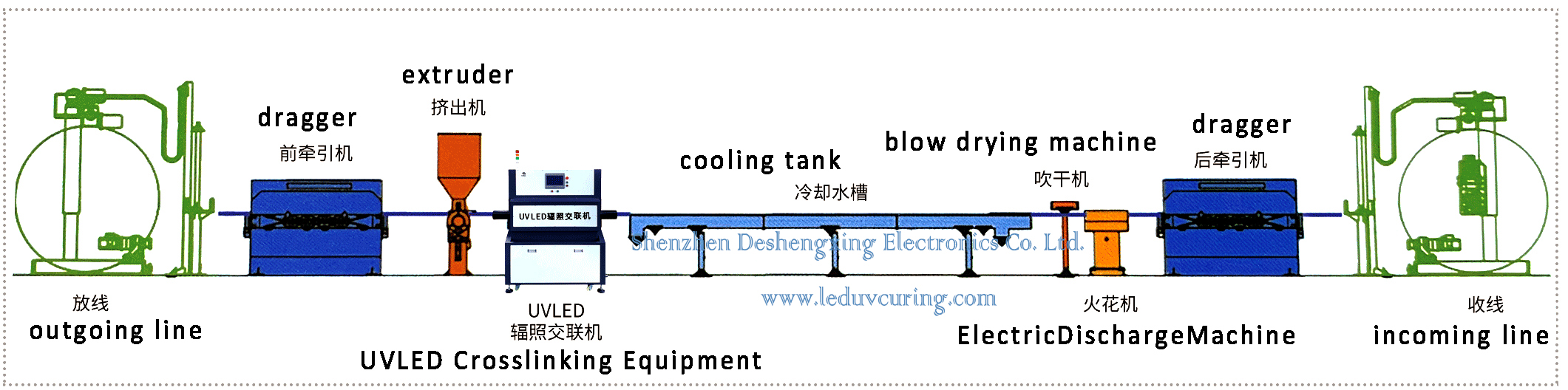

LED-UV type Cable UV Light Irradiation Crosslinking Machine adopts a circular cavity tunnel structure, installs a self-developed UV LED light source and forms a tunnel to the central area, whose radiant power can be infinitely set within the scope of 0~100%.

Structural Characteristics of UV LED Radiation Cable Crosslinking Equipment :

1.The tunnel structure is opened by turning over, which is convenient for operation, cleaning and thread taking

2.Using intelligent touch man-machine interface, monitoring data, operation buttons, and power setting are all completed on the touch screen interface

3.One-key start function coexists with separate start

4.The cooling method adopts refrigerator refrigeration, and the circulating medium uses automobile special antifreeze

5.It is connected to the smoke removal mechanism and discharged outside through the air duct

Characteristics of UV Light Irradiation Crosslinked Cable Equipment :

1.Wide applicability

Ultraviolet cross-link equipment is suitable for online cross-linking of polyethylene or low-smoke halogen-free flame-retardant polyolefin low-voltage wires cables. The maximum cross-linking thickness of the production can reach about 2mm (non-frame retardant type, high density or linear low density polyethylene cable material).

2.Low cost

The price of ultraviolet light crosslinking equipment is only 1/10 - 1/5 of electron beam equipment. The installation only needs to add the equipment on the original basic production line, and no other equipment investment is needed. Because the ultraviolet light production method completes crosslinking at one time, it can save other human and material resources, and its production cost is much lower than other crosslinking methods.

Performance Indicators of LED UV Irradiation Crosslinking Machine :

Power Supply | AC380V, 10φ50HZ |

Applications | UV Crosslinking of cables |

Suitable Size | Effective diameter 0-60mm, effective length 1000mm |

Size of Machine | 1700*1050*1900mm L*W*H |

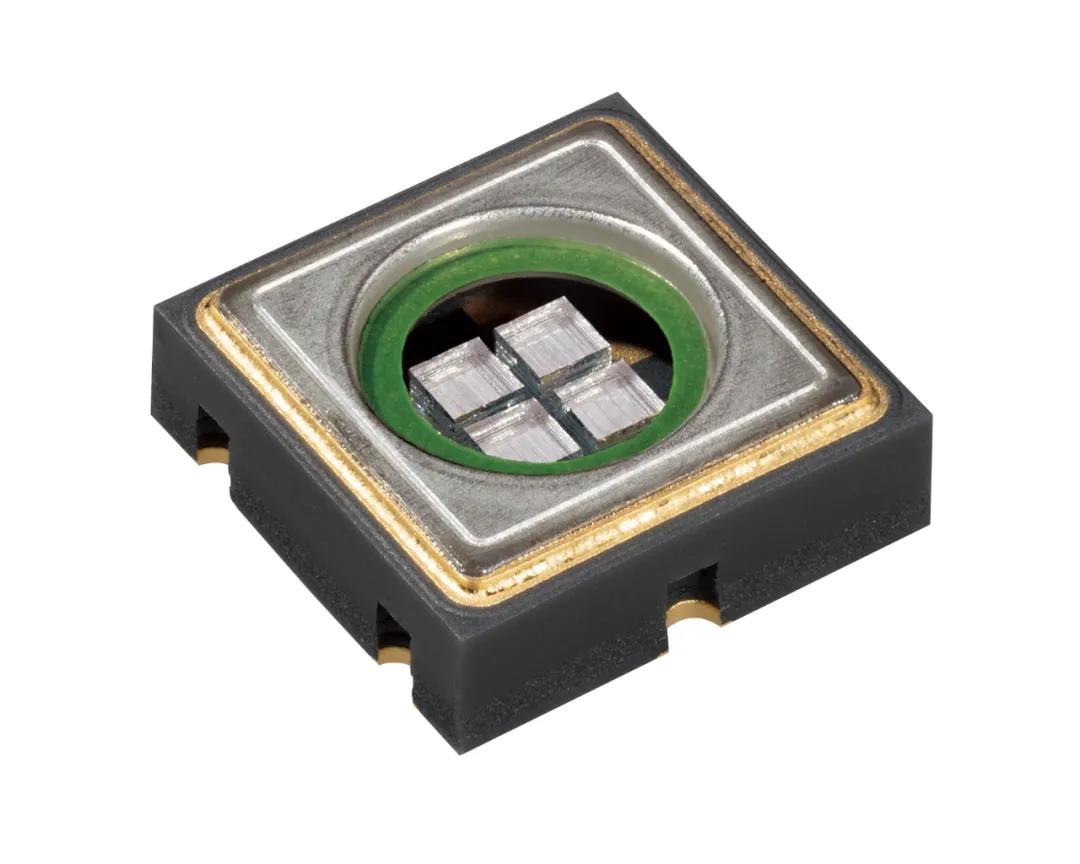

UV LED Light Source | Equipped with 14 UV LED lamp sets, forming a circle. Using imported chip, water cooling heat dissipation, prolong the service life of UV LED lamp, with advanced aggregated optical system, high intensity of light source, to ensure fast light crosslinking reaction |

Life of Light Source | >30000 hours |

Cooling Method | External chiller, through special coolant circulation, inside circulation cooling |

Cooling System | 14 temperature probes intelligent control |

Structure Design | Lamp source adopts front and rear, opening and closing mode, convenient for threading. Integrated design of the whole machine, beautiful, generous, and save space. |

Irradiation color | Ultraviolet |

Temperature Control Range | Room temperature -40℃ |

Temperature Measuring Point | 14 pcs |

Accuracy of Temperature Control | ±2℃ |

Power Consumption | About 14KW |

Material | SS41# steel plat is used the case after anti-rust treatment inside and outside. |

Control Method | PLC + human machine interface (HMI) |

Safety Device | Input circuit breaker, emergency stop button, real-time detection of lamp source status |

Configuration | Host machine, water chiller (optional), power line 3m |

Outgoing Line Speed of LED UV Radiation Polyolefin Crosslinked Machine :

Cross-Sectional Area of Conductor (mm2) | Thickness (mm) | Production Speed (m/min) | Hot Prolongation (%) | Thermal Contraction (%) |

2.5 | 0.7 | 60-110 | 50-100 | 0-3 |

4 | 0.7 | 60-110 | 50-100 | 0-3 |

6 | 0.7 | 60-110 | 50-100 | 0-3 |

10 | 0.8 | 40-100 | 50-100 | 0-3 |

16 | 0.8 | 40-100 | 50-100 | 0-3 |

25 | 0.9 | 40-90 | 50-100 | 0-3 |

35 | 0.9 | 40-90 | 50-100 | 0-3 |

50 | 1.0 | 30-90 | 50-100 | 0-3 |

70 | 1.1 | 30-80 | 50-100 | 0-3 |

95 | 1.1 | 25-80 | 50-100 | 0-3 |

120 | 1.2 | 25-70 | 50-100 | 0-3 |

150 | 1.4 | 20-60 | 50-100 | 0-3 |

185 | 1.6 | 20-50 | 50-100 | 0-3 |

240 | 1.7 | 15-30 | 50-100 | 0-3 |

300 | 1.7 | 15-25 | 50-100 | 0-3 |