Some customers feel that the curing effect of UV LED curing machine depends on UV LED light source. Although UV LED light source plays a decisive factor in UV glue solidification, it is difficult to achieve good curing effect only by replying on UV LED light source. It is also affected by following important factors.

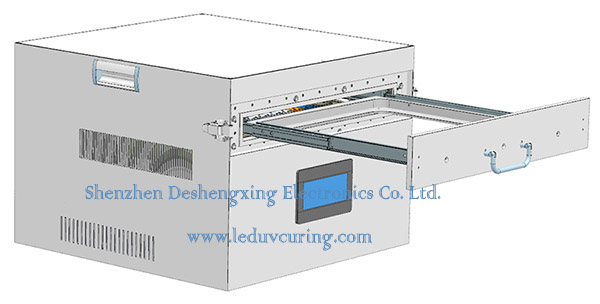

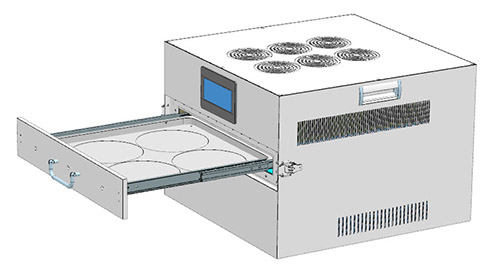

1.Cooling system

The heat dissipation system of UV LED Curing Chamber has an important influence on its stable and smooth operation. UV LED Curing Machine with good heat dissipation effect can quickly discharge the heat from UV LED chips. It can not only reduce the temperature of the UV LED Lamp beads, but also reduce the temperature rise of the surface of the object to ensure the stability of the equipment and extend the service life of the UV LED Curing Chamber.

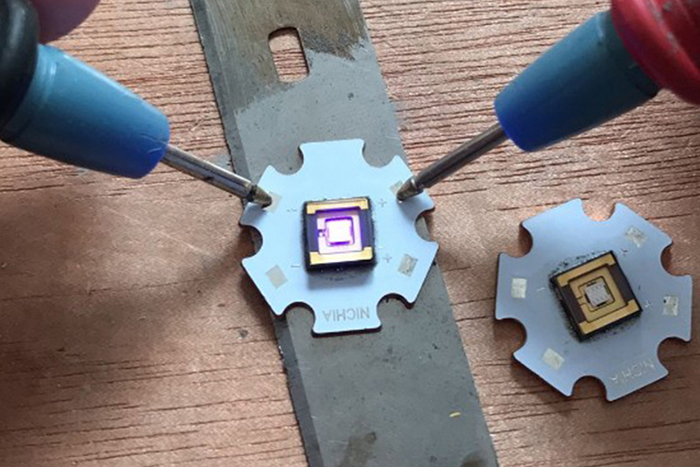

2.The quality of UV LED light beads

The light bead of UV LED Curing System Machine is the core part of the whole UV curing machine. The irradiation head generates an ultraviolet light source through the UV LED light chips. But different quality of UV LED lamp bead, its light effect, energy, stability of light source, light uniformity are very different. The production of UV LED curing equipment by DSXUV, the use of imported lamps beads, the quality of light source will be guaranteed.

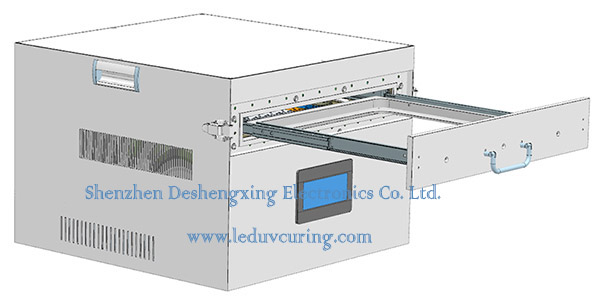

3.Control system

The control system of UV LED Curing Light Equipment carries the circuit operation control of the whole set of UV LED curing machine, providing technical guarantee for the maneuverability and safety of the equipment. The light source controller produced and developed by DSXUV can set power of light source, irradiation time and control mode according to the actual working conditions. It also can be connected with external pedal control switch or RS232 serial port.

4.Customized UV LED curing light source comes to DSXUV

As one of the earliest manufacturers of UV LED Curing Light Source in China, we provide customers with a full range of UV curing solutions, including a complete range of standard products and customized UV LED curing system machines according to customer requirements. If you have UV LED curing requirements, you can contact us at any time, DSXUV dedicated to your service.