For UV INT 140 Energy Meter and UV INT 150 Energy Meter, you don’t have to worry about high temperature now. Shenzhen Deshengxing Electronics Co., Ltd. produces high temperature resistance protective shell for UV energy meter, which can be super high temperature resistance and used in UV furnace for a long time. The heat generated by the UV light source can be dissipated through this device without affecting the UV energy meter.

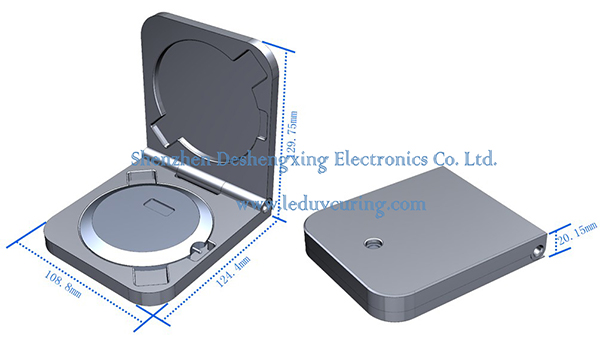

Parameters :

UV-INT 140 Integrator : 178*169*25mm (L*W*H) 1.35kg

UV-INT 150 Integrator : 109*125*21mm (L*W*H) 1.05kg

Advantages : super high temperature resistance, long service life, can not be affected by high temperature for a long time.

Therefore, customers who have bought 250-410nm UV INT140 or UV INT150 Integrator UV Energy Meter before can buy a separate high temperature protection device for UV Integrator. UV energy meter only installed on the protective shell will not appear black screen phenomenon. The data remained stable over time. You don’t need to spend more money everyday year to calibrate.

Our company sales UV detection instrument, like UV energy meter, for long term. According to many years of experience, all UV energy meters on the market occasionally appear in the use of black screen phenomenon, display is burned, date is not stable and other conditions. Actually, these phenomenon are often caused by UV energy meter high temperature tolerance. These problems can be solved well by adding a heat dissipation protection shell outside the exposed instrument. It can also save you the cost of calibration, debugging and maintenance.

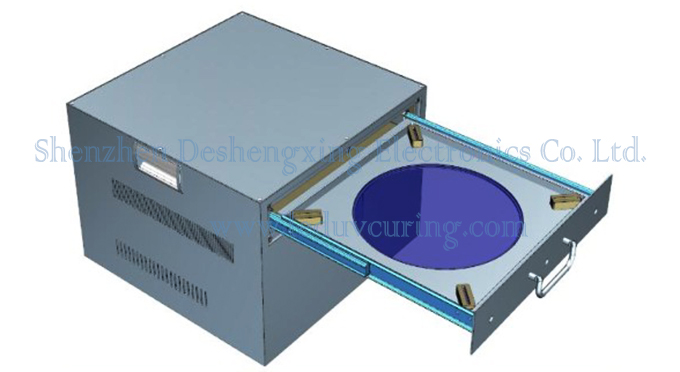

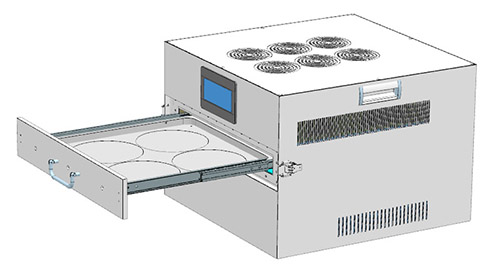

UV Curing Furnace temperature is very high, a lot of UV energy meter put into the detection will show a black screen, screen is burned, data keep beating and other faults. Shenzhen Deshengxing Electronics Co., Ltd. special UV energy meter protective shell can be very goods protection of UV energy meter in use without problems.

Note : many customers buy small UV energy meter does not show easily, sometimes the data is unstable, or the display was directly burned. These conditions are caused by high temperature intolerance. Therefore, in view of these reasons, Germany has developed a special high temperature resistant UV energy meter. UV-Integrator 140 Energy Meter, referred to as UV 140, UV-INT 140 energy meter. The body of the high heat dissipation is material is twice as large as the original UV 150 Energy Meter Tester. However, UV INT 140 Energy Meter is stable in use, reducing the failure rate, long service life, and less need for calibration and maintenance.

The heat dissipation effect of UV DESIGN UV-Integrator 140 Light Meter Equipment is better than that of UV-Integrator 150 Light Meter Equipment, because the plate UV INT 140 Integrator is larger and the heat dissipation is faster. Under the same temperature and the same type of equipment, the data obtained by the UV Integrator 140 test is more accurate.