Size of Controller

| Outside Dimensions | L330*W140*H130mm | Power | 50W |

| Cooling Method | Fan Cooling | Power Input | 100-240V AC 50-60HZ |

| Material / Weight | About 3.5Kg Black Sheet Metal | LED Head Number | One, Independently controlled |

| RS232 串口通信

RS232 Serial Communication

| 可查询和调节强度、时间、模式 Can query and adjust intensity, time and mode | Display and Operation | Touch screen, time, intensity, mode adjustable |

| LED Cumulative Time |

Record accumulated using time

| Control Method | Connected with MCU, PLC and other automatic equipment to control and feedback the work state |

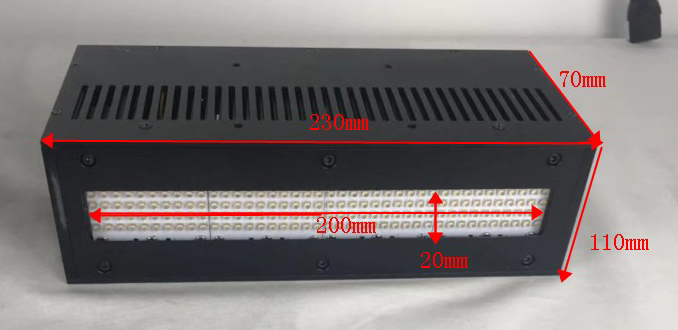

Size of Emitted Head

| Emitted Area | 200*20mm | Power | <350W | |||

| Outside Dimension | L130*W130*H130mm | Recommended Height | 5mm | |||

| Cooling Method | an Cooling | Wavelength | 365 | 385 | 395 | 405 |

| Material / Weight | Sheet Metal / About 3.3Kg | Luminous Power (mW/cm2) | 2200mW | 2500mW by EIT | ||

| LED Life | 20000 H | |||||

| Monitoring Methods | Temperature | Connection Cable | 2/5m (Customizable) | |||

Irradiation Head of 200*20mm Large Area LED UV Curing Machine

UVLED surface light source curing products, if you need to cure the following products, it is recommended to use our UVLED surface light source

At present, uvled radiation-cured products have penetrated into all aspects of industrial production and daily life, and are almost ubiquitous. Here are just a few typical examples.

(1) Coated discs, optical fibers, magnetic tapes, magnetic cards, high-end goods bags, photographic film, magazine covers, vacuum metal plastics, cans, furniture veneers, laminates, wall panels, vinyl tiles and tiles, galvanized metal pipes and Leather decoration, etc.

(2) uvled ink lithographic offset printing, letterpress printing, flexographic printing, gravure printing and screen printing;

(3) uvled adhesive automotive headlights, pressure sensitive labels and transfer printing, electronic device packaging and cladding, medical plastic parts assembly, etc.;

(4) Electronic device printed circuit board conformal coating, resist, solder resist, character ink, anti-dry film, protective coating, etc.;

(5) Other printing plates, medical devices, dental fillings, cosmetic boxes, ophthalmic lenses, golf balls, trophies, snowboards, snowmobiles, advertising signs and other coating curing or decoration, and three-dimensional optical casting processing.

The main application areas of UV LED surface light source curing:

Wood coating - wood primer and surface varnish and paint: filler (filling the interior and surface voids of the board); water-based furniture coating.

Plastic coatings - thin film coatings and hard coatings: automotive parts, instruments, optical discs, credit cards, window films, and metallized plastic low-profile coatings for automotive headlights and lighting components.

Paper coating - surface glazing, metallized paper substrate coating for decorative paper, labels, cards and paper.

Floor coating - vinyl carpet, vinyl silicon, parquet flooring.

Metal coatings - food cans, automotive and instrument decoration, traffic tunnel wall panels.

Silicon germanium coating (paper/film) - release liner, label, casting.

Electronic coatings - conformal coatings, encapsulating compounds, photoresists, soft (hard) disks, optical disks, video tapes, magnetic tapes, optical fibers.

Inks - lithography (cardboard boxes, flexible packaging, magazines, publications), screen printing (plastic labels, plastic bottles, foils, paper and cardboard packaging) and printing.

Adhesives - laminates (paper or film / wood, film, paper, foil, etc.), general bonding (automotive parts, optics), and pressure sensitive adhesives (labels, contact papers/films, etc.).

Crosslinking - heat shrinkable film, electrical insulation material.

No comments:

Post a Comment