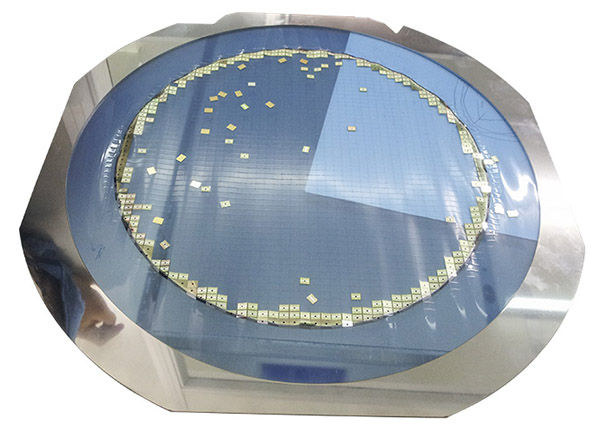

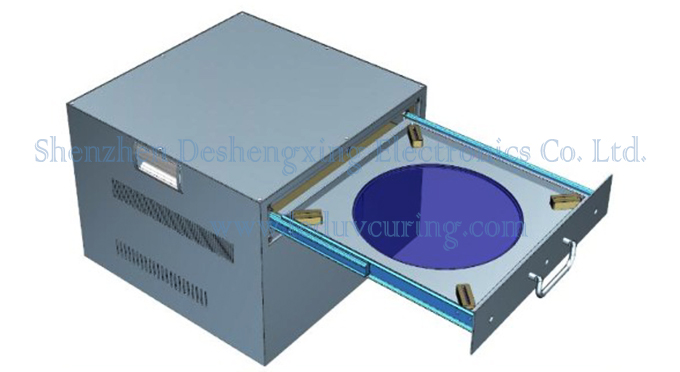

UV film is a special formula UV coating on coated PET, P0, PVC, EVA film base material surface, is a specially designed for semiconductor chips, special optical glass (wafer of silicon, filter glass), special metal and ceramic substrates and flexible electronics and some small thin fragile parts processing production of fixed, protection, bearing with designed a new type of adhesive products. This material adopts specially polyolefin (PO) and polyester (PET) film as raw material, coated with special adhesive, through dust-free high temperature coating process. UV film with high adhesion, high tensile strength, adaptability, balanced extension and other characteristics, easy to fix some small particles or fragile ultra-thin sheet, so that the material in the grinding, processing and cutting process does not slide, do not fly, no water seepage. At the end of the processing, the UV film after a specific ultraviolet energy irradiation to make the tape lose adhesion, it is easy to separate the product from the tape, and no damage, no residue, very good to meet the semiconductor and optical industry special materials processing process. UV tape can be customized according to customer requirements of various thickness, viscosity and processing customer required shape and size. The principle of UV adhesive is mainly concentrated in the adhesive formula to add a photo-initiator, so that it in a specific value of UV LED light curing, trigger the internal function, making the original high adhesive surface suddenly lose viscosity, so as to meet the requirements of the process.

No comments:

Post a Comment