The technological process of UV Irradiation Cable Crosslinking Equipment is that UV light is used as the radiation source, and the mixed photo-crosslinking polyolefin is extruded and coated on the conductive wire core, and then it immediately enters the special irradiation equipment for melting state optical crosslinking. Photo-crosslinked polyolefin insulated wire and cable products can be obtained after the light irradiation crosslinked insulated wire core is cooled at different temperatures and other subsequent processing.

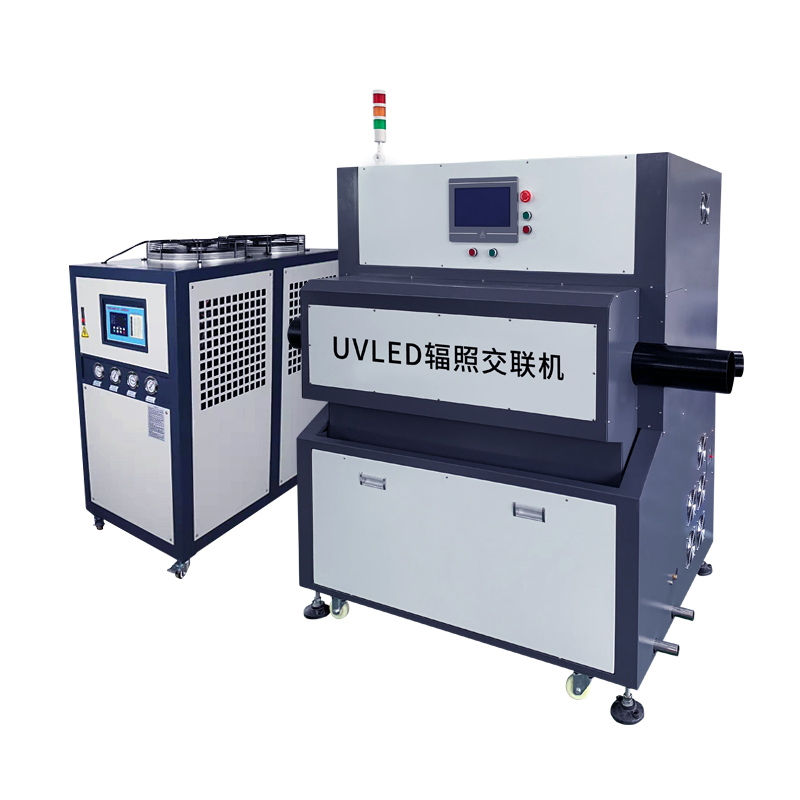

Cable UV Light Irradiation Crosslinking System Machine only needs to be slightly changed on the original ordinary extrusion production line. The equipment covers a small area, with upper traction, irradiation box, electrical control cabinet, etc., can meet the requirements to produce UV irradiation crosslinking polyethylene wire and cable products. Increase the traction, so that the conductive wire core to maintain a certain tension. Always in the center of the box during operation to ensure the best irradiation effect. The irradiation box adopts uniform configuration and characteristic design of reflective concentrated UV light source, and the electric control system ensures that the ultraviolet intensity and temperature at the center of the irradiation box are in the best working conditions. The efficient optical traction system can quickly trigger polyolefin crosslinking reaction under UV light, so that the equipment can achieve a continuous production speed of tens of meters per minute. The water temperature of hot, warm, and cold is cooled step by step to ensure the stability of the three-dimensional network crosslinking structure.

What are the advantages of LED UV Radiation Polyolefin Crosslinked Machine?

1.More Intelligent

Using intelligent detection system, real-time detection of equipment operating temperature, flexible, dual mode operational

Manual mode: simple and convenient, easy to understand, easy to operate

Automatic mode: intelligent speed measurement system of equipment, real-time online detection of production speed.

The system can follow the speed of production, adjust the UV energy intensity, effectively solve the general crosslinking in the initial stage of line change and the production speed of the tail part of the product crosslinking excessive or insufficient defects, greatly reduce the generation of waste, effective cost saving.

2.More Safety

Earth leakage circuit-breaker

Warehouse door detection system: when the warehouse door is not closed well, the system will issue an alarm to avoid accident

Light source detection system: can effectively avoid the generation of waste

Speed detection system: the system can adjust the UV energy intensity according to the speed of production, and save materials intelligently and effectively

Abnormal tracing system: when the equipment is abnormal, the system is traceable and check the records

3.More Energy-Efficient

DSXUV Intelligent LED UV Light Irradiation Crosslinking Cable Equipment adopts the new process LED, its lamp power consumption is saver 70% than the ordinary crosslinking. The crosslinking speed is more than 2 times of the original, which solves the disadvantages of thick insulation, irradiation impenetrability and slow speed. Small footprint, more reasonable design, economizing steam crosslinking process, greatly improving production efficiency, saving cost and time.

No comments:

Post a Comment