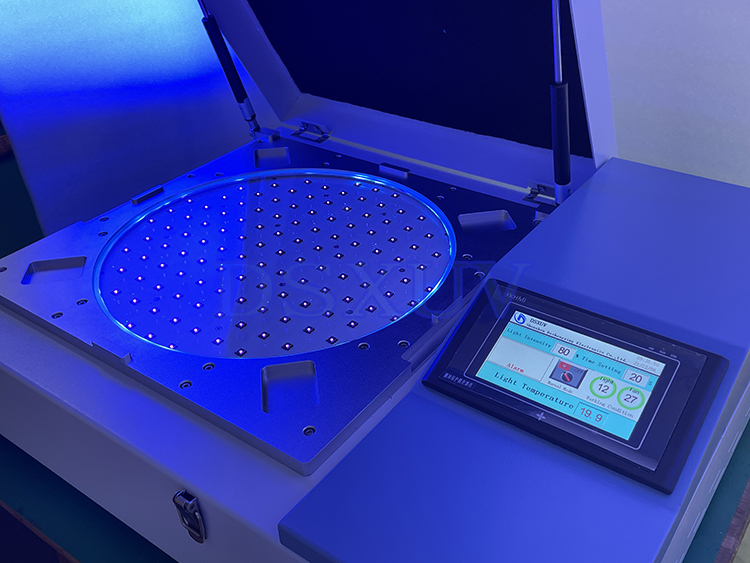

UV LED curing machine is a kind of mechanical equipment that can emit high intensity UV rays after being improved by science and technology. At present, it has been widely used in optics, medical equipment, electronics, automation, communication and information industries. Although the types and styles of UV LED curing machines vary depending on the products they are curing. However, the UV curing device is basically divided into five parts: light source system, heat dissipation system, control system, conveying system and box body. Today we will share the relevant knowledge of UV machine light source system.

Not only refers to UV LED light, but also UV LED lights and the circuit configuration system that can maintain the normal operation of UV LED light; including: UV LED lights, lamp boxes, transformers (ballasts), and capacitors.

First, the choice of UV LED curing light power.

1.1. The service life of the UV LED is generally 15000-20000 hours, and it should be replaced after attenuation, because the intensity of the ultraviolet light emitted by the UV LED lamp beads during this period has weakened seriously, which greatly reduces the curing effect. In the process of use, if there is any UV LED light chips attenuation, please replace it in time. In this way, all UV rays can be effectively radiated to the UV ink or varnish to ensure a certain penetrating power.

1. 2. The power of the ultraviolet light emitting diode lamp is the radiant energy of the UV LED lamp, also known as the penetrating power. At first, it must meet the requirements of spectral wavelength and power density absorbed by UV ink (varnish/ink). If the power of the UV LED curing lamp is not enough, even if the illumination time is longer and how many times the UV curing equipment is passed, the product will not be fully cured. On the contrary, the surface layer of UV ink (varnish) will be aged, closed, friable, etc. In the meantime, the adhesion of the ink (varnish) will not be good, which will make the inter layer binding force worse. Because the low-power UV curing light can not penetrate the bottom of the ink layer, resulting in the bottom is uncured or dry.

1. 3. The power/intensity of the UV LED curing lamp generally meets the requirements over 600mW/cm2, but the higher the power, the greater the heat. Generally, it is used air cooling. But if it is high power (over 8W/cm2), especially curing UV ink coating, recommended to use water cooling.

Second, the reflector we usually use for UV LED curing machine is focusing type and parallel light type. The focusing type is generally used, which its characterized is concentrated reflected UV LED light energy and high photo-curing efficiency, which is conducive to the curing of ink with thick ink layers and can completely deeply cure the layers of the ink. The focusing lens is widely used in spot type UV LED curing light source. But we produce surface type UV LED curing light source, UV tape UV curing systems and other large area UV LED curing equipment are directly installed with a piece of glass. Because the beads themselves have lenses.

The above explanation is that DSXUV collects relevant information about the UV LED curing machine light source system. DSXUV is a manufacturer specializing in the development and production of various UV LED curing light sources and UV LED curing systems. Welcome friends from all walks of life to exchange guidance. If you want to know more about the UV LED curing machine, please contact customer service online, email (uvcure@uvspacelight.com) or call our service hotline (+86-18924372460) for consultation, we will wholeheartedly provide you with high-quality service! Thank you!

No comments:

Post a Comment