About the Depth of UVC-LED Disinfection 15 Questions

1.What is Ultraviolet Disinfection ?

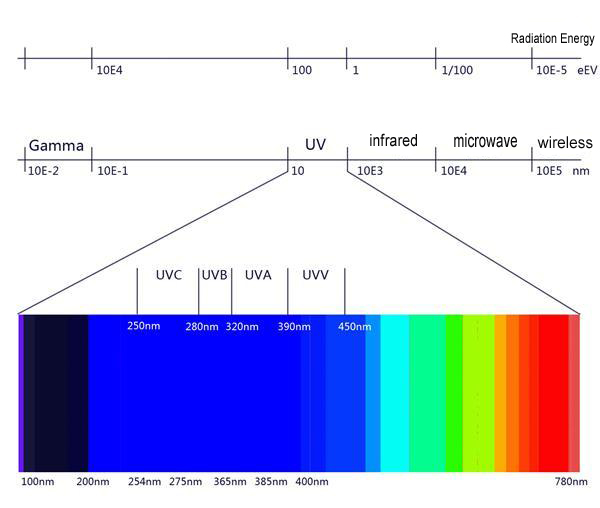

Ultraviolet disinfection is the use of appropriate wavelength of ultraviolet radiation can destroy the microbial body cells DNA or RNA molecular structure, resulting in growth cell death and / or cell death, to achieve the effect of disinfection. UV disinfection technology is based on the modern epidemic prevention science, medicine and photo-dynamics, using specially designed high efficiency, high intensity and long life UVC band UV Light Irradiation water. Water will be all kinds of bacteria, viruses, parasites, algae and other pathogens directly killed.

2.The antivirus mechanism of Ultraviolet Disinfection

Research shows that UV radiation mainly kills microorganisms (bacteria, viruses, spores and other pathogens) through radiation damage to microorganisms (bacteria, viruses, spores and other pathogens) and destroys the function of nucleic acid, so as to achieve the purpose of disinfection. The effect of UV radiation on nucleic acid can lead to the break of bonds and chains, the cross-linking between strands and the formation of photo-chemical products, etc., thus changing the biological activity of DNA and preventing the replication of microorganisms themselves. Such UV damage is also fatal.

3.The advantages of Ultraviolet Disinfection

A.Bactericidal rapid and efficient, the use of ultraviolet on bacteria, viruses can be generally used in one to two seconds to achieve 99%-99.9%of the bactericidal rate, and can kill some chlorine disinfection method can not inactivate the bacteria (spores and viruses), but also to a certain extent to control some higher aquatic organisms such algae and red worms.

B.Bactericidal broad-spectrum, ultraviolet technology in all current disinfection technology, bactericidal broad-spectrum is the highest.

C.The integrated equipment is simple in structure, compact and light, occupying little space.

D.Relatively safe operation management, basically no use, transportation and storage of other chemicals may bring about highly toxic, flammable, explosive and corrosive safety hazards.

E.Completely silent.

4.Can you have radiate to human body or harm when ultraviolet sterilization disinfection product is used?

Our products have built-in chips, and all the work is done in an airtight environment. The shell is metal packaging, and there is absolutely no risk of leakage. In addition, our products have been tested for Ultraviolet Leakage, which fully conforms to the national health and family planning commission’s regulations on the health and safety evaluation of disinfection products.

5.Does the water that via Ultraviolet Ray Disinfection drink directly whether can you have harm to human body ?

Because UV Disinfection Technology does not need to add any chemical agents, so it will not cause secondary pollution to the water and the surrounding environment. Even if excessive treatment will not produce water quality problems, the physical and chemical properties of water is basically the same, do not increase the taste of water, do not produce such as trihalomethane disinfection by-products.

6.Is UV Disinfectant products suitable for people ?

UV disinfection products are suitable for all groups of people, especially for elderly, children, pregnant women and other vulnerable groups to provide a higher quality of life. It is also very suitable for the humid areas, such as the southern plum rain season, the cost of tableware easily moldy, and mold is not easy to clean kill, easy to harm human health.

7.Compared with other disinfection methods, what are the advantages of ultraviolet disinfection products ?

A.Many bacteria killed condition that needs a certain temperature and a certain amount of time, such as common, hepatitis b virus in above 120℃ for 20 minutes to kill. So the way water is boiled and boiled doesn’t kill germs completely. However, ultraviolet disinfection directly reaches the molecular structure of DNA or RNA in cells, which can achieve the effect of sterilization and disinfection more efficiently.

B.For example, traditional families will use cupboards and other storage tableware, but the traditional cupboards are not sealed or sealing is not good, will be dust sewage and insects, ants, rats and other secondary pollution. In addition, traditional crockery does not have drying function, the area with higher humidity, cost of woodiness tableware is easy moldy, and the aflatoxin in mould is a kind of bacterium that cause cancer, kill more different again, very big to hidden trouble of human body health. Use ultraviolet disinfection product to be able to undertake sterilization disinfection to the article that needs disinfection at any time and place.

8.The relationship between the power of ultraviolet disinfectant products and the effect disinfectant area.

The small sized ultraviolet ray of 4W disinfects the lamp, reliable disinfection space is the space of 6 square meters. Because the space is small light can reflex nevertheless, antiseptic effect can increase 50% left and right sides.

12W is suitable for less than 20 square meters.

30W is suitable for within 20-35 square meters.

40W is suitable for within 30-45 square meters.

9.Life of Ultraviolet Lamp Tube

The effective life of hot cathode is 8000 hours, and that of cold cathode is over 20000 hours.

10.Lamp Material Classification of Ultraviolet Disinfection Products

Classification of Ultraviolet ray sterilization lamp tube : quartz glass tube, high borax glass tube, ordinary glass. The quartz glass tube material is actually a kind of low-pressure mercury lamp, like ordinary fluorescent lamp, uses low-pressure mercury vapor (<10, 2pa) to emit ultraviolet light after being excited. The lamp tube of general bactericidal lamp uses quartz glass to make. Because quartz glass has very high transmission ray to ultraviolet each wave band, amount to 80%, 90%. it is the best material that makes bactericidal lamp. Although quartz is more expensive, all mercury vapor lamps for UV polymerization are made of quartz and are usually made of bake-lite, plastic or ceramic.

The main reason is that quartz has three important properties very suitable for the production of ultraviolet lamp : 1). transparent to ultraviolet light, no absorption or very little absorption of UV. 2). it is a poor conductor of heat. 3). low thermal expansion coefficient, quartz purity and the presence of other trace compounds will affect the emission characteristics of lamp.

The tube is a fused quartz tube, the thickness of the tube wall is about 1mm, the outer diameter is 20~25mm, the total length of the arc lamp is 2m, the complex electrode layout (electronic emitter, base, conductor, etc.) is sealed at both ends of the quartz tube, the quartz tube contains mercury for transmitting energy and starting gas, usually argon. When the lamp is energized, an arc occurs between the poles. With the increase of voltage between electrodes, the temperature of the gas increases, and mercury evaporates, producing mercury vapor arc light and emitting characteristic ultraviolet light. When fully powered, the lamp also emits visible and partial infrared light.

Borax glass tube kind material, because cost concern and utility are different, also useful ultraviolet ray penetrates the borax glass tube that <50% to replace quartz glass. High boron glass production process and energy-saving lamps, so the cost is very low. But it is far from the performance of quartz glass tube ultraviolet sterilization lamp. Its sterilization effect has considerable different. The ultraviolet light intensity of high boron lamp tube is easy to attenuate, after lighting for hundreds of hours, the ultraviolet light intensity drops to the initial 50%,70%. However, after lighting 2000~3000 hours, the intensity of ultraviolet ray only reduced to 80%, 70% of the original, the light decline is far less than the high boron lamp.

Ordinary glass material is kind of ordinary glass with higher ultraviolet light, much higher than boron glass, slightly lower than quartz glass, light decay is still larger than quartz sterilization lamp, and can not produce ozone.

11.Ultraviolet allergy is right sunshine allergy namely, it is insolation that gets the ultraviolet ray in sunshine as a result of the skin, make the skin appears read swollen, SAO urticant wait for unusual reaction, cause skin allergy thereby. Generally speaking, the crowd of ultraviolet allergy is allergy sex constitution mostly. Accordingly, allergies can occur as long as the skin is exposed to a little sunlight. The symptom of ultraviolet allergy basically is the occurrence after the skin is basked in rad and swollen, burning, ache, SAO urticant, erythema, allergy is more serious, can appear even have a headache, systemic calorific, disgusting, lack of power, vomiting wait for unwell symptom. But the product of general ultraviolet sterilization disinfection can have protective layer, won’t produce an effect to this kind of crowd commonly.

12.How do ultraviolet sterilization lamps produce ozone ?

When the ultraviolet ray irradiates in the ray periphery to be able to produce the uneven electric ion, like this can cause the oxygen molecule in the air to produce the ionization, causes it to recombine into ozone.

13.The difference between UV LED and Mercury Lamp

UV LED has the advantages of high efficiency, energy saving, environmental protection and long life.

High efficiency : out-of-the-box, no need to preheat, can be set when the product after bright.

Energy saving : UV mercury lamp is a wide range of band, and the curing or sterilization of one of the main function is one of the wavelength. Other bands are useless, waste, absorbed by the product and converted into heat energy, this is also the product of mercury lamp irradiation than UV LED irradiation temperature higher. UV LED is a single wavelength, for UV coating, choose the matching LED wavelength curing. Compared with traditional UV mercury lamp, UV LED can save 60% energy.

Environmental Protection : mercury lamp contains mercury and other harmful substances, and the low-wave ultraviolet light in the mercury lamp will react oxygen in the air into ozone, which makes it necessary to install the exhaust system when using mercury lamp, and the long-wave ultraviolet light of mercury lamp is very large to the human radiation, need to be completely closed and shading treatment. UV LED environmental noise pollution, no harm to the human body.

Life : UV LED light source is cold light source with low calorific value. The life of UV LED is over 20,000 hours, while the life of mercury lamp is about 1,000 hours.

14.History of UV LED

UV LED is also called ultraviolet light emitting diode. The core part of UV LED is a chip composed of P-type semiconductor. There is a transition layer between P-type semiconductor and N-type semiconductor, which is called PN junction. In the PN junction of some semiconductor materials, the combination of the injected minority carries and majority carriers will release the excess energy in thee form of light, thus directly converting electrical energy into energy. The injection electroluminescent principle of the production of diodes called light-emitting diodes, commonly known as LED. When it is in a forward operating state (that is, both ends plus a positive voltage), the current from the LED anode to the cathode, semiconductor light-emitting diode in the history of what is it ?

Electroluminescence was first discovered on a piece of silicon carbide by Henry Joesph Round in 1907, but due to the dim light emitted and the difficulties in the silicon carbide experiment at that time, it was finally abandoned.

Further experiments were carried out in 1920 by German physicists Bernard Gooden and Robert Wichard Pohl, who obtained phosphorus from zinc sulfide doped with copper. But in the end the light wad so dim that it stopped again.

1936, George Destriau published a report on the luminescence of zinc sulfide power, which is widely credited with the term electroluminescence.

British scientists used gallium arsenide in the 1950s to create the first “modern” light-emitting diode in the early 1960s. The abbreviation of LED is light emitting diode. Its basic structure is a piece of electroluminescent semiconductor material, placed on a shelf with leads, and then sealed around with epoxy resin, to protect the internal core wire, so LED seismic performance is good.

Gallium phosphide itself was used as a luminescent material in the mid-1970s and soon gave off a very pale green light. Light-emitting diode using a gallium bisphosphate chip will be able to shine yellow. The yellow light-emitting diodes were made in Russia around this time using silicon carbide.

In the mid-1980s, gallium aluminum arsenide was used to make the first generation of ultra-bright light-emitting diodes, first red, then yellow and finally green.

In the early 1990s, indium gallium aluminum phosphorus was used to produce ultra-bright light-emitting diodes that emit orange-red, orange, yellow and green light. The first blue light-emitting diodes were also made in 1990 using silicon carbide.

It was only in the mid-1990s that gallium nitride was used to make ultra-bright blue light-emitting diodes, and it was soon by indium gallium nitride to make high-intensity green and blue light-emitting diodes. Ultra-bright blue light chips are the basis for white light-emitting diodes, which use a coating of fluorescent phosphorus that absorbs the blue light and emits it as white. The end result has always been to use the same technique to create any color.

15.So, what are the main features of UV LED as light-emitting diode ?

A.No or little organic solvent volatilizes, UV uses UV light source does not contain mercury, belongs to environmental protection product.

B.Because UV LED UV light can immediately ink curing, so it saves other technologies need drying time, greatly improve production efficiency.

C.Suitable for a variety of substrates : flexible or rigid, absorbable non-absorbent materials.

D.UV LED curing technology can also reduce the curing process of two-way drag phenomenon. In general, UV LED curing technology not only simplifies the printing process, but also enables end users who do not have screen printing knowledge to achieve the described printing effect.

E.UV LED curing system does not generate heat, UV LED technology can significantly reduce the heat generated during the curing process, so people can make UV printing on thin plastic and other materials.

F.Compared with traditional metal halide lamps, UV LED can save 2/3 of the energy. The service life of UV LED chip is many times that of traditional UV lamps. Another important advantage of UV LED technology is that UV LED does not need preheating and can be turned on or off at any time as required.

1.What is Ultraviolet Disinfection ?

Ultraviolet disinfection is the use of appropriate wavelength of ultraviolet radiation can destroy the microbial body cells DNA or RNA molecular structure, resulting in growth cell death and / or cell death, to achieve the effect of disinfection. UV disinfection technology is based on the modern epidemic prevention science, medicine and photo-dynamics, using specially designed high efficiency, high intensity and long life UVC band UV Light Irradiation water. Water will be all kinds of bacteria, viruses, parasites, algae and other pathogens directly killed.

2.The antivirus mechanism of Ultraviolet Disinfection

Research shows that UV radiation mainly kills microorganisms (bacteria, viruses, spores and other pathogens) through radiation damage to microorganisms (bacteria, viruses, spores and other pathogens) and destroys the function of nucleic acid, so as to achieve the purpose of disinfection. The effect of UV radiation on nucleic acid can lead to the break of bonds and chains, the cross-linking between strands and the formation of photo-chemical products, etc., thus changing the biological activity of DNA and preventing the replication of microorganisms themselves. Such UV damage is also fatal.

3.The advantages of Ultraviolet Disinfection

A.Bactericidal rapid and efficient, the use of ultraviolet on bacteria, viruses can be generally used in one to two seconds to achieve 99%-99.9%of the bactericidal rate, and can kill some chlorine disinfection method can not inactivate the bacteria (spores and viruses), but also to a certain extent to control some higher aquatic organisms such algae and red worms.

B.Bactericidal broad-spectrum, ultraviolet technology in all current disinfection technology, bactericidal broad-spectrum is the highest.

C.The integrated equipment is simple in structure, compact and light, occupying little space.

D.Relatively safe operation management, basically no use, transportation and storage of other chemicals may bring about highly toxic, flammable, explosive and corrosive safety hazards.

E.Completely silent.

4.Can you have radiate to human body or harm when ultraviolet sterilization disinfection product is used?

Our products have built-in chips, and all the work is done in an airtight environment. The shell is metal packaging, and there is absolutely no risk of leakage. In addition, our products have been tested for Ultraviolet Leakage, which fully conforms to the national health and family planning commission’s regulations on the health and safety evaluation of disinfection products.

5.Does the water that via Ultraviolet Ray Disinfection drink directly whether can you have harm to human body ?

Because UV Disinfection Technology does not need to add any chemical agents, so it will not cause secondary pollution to the water and the surrounding environment. Even if excessive treatment will not produce water quality problems, the physical and chemical properties of water is basically the same, do not increase the taste of water, do not produce such as trihalomethane disinfection by-products.

6.Is UV Disinfectant products suitable for people ?

UV disinfection products are suitable for all groups of people, especially for elderly, children, pregnant women and other vulnerable groups to provide a higher quality of life. It is also very suitable for the humid areas, such as the southern plum rain season, the cost of tableware easily moldy, and mold is not easy to clean kill, easy to harm human health.

7.Compared with other disinfection methods, what are the advantages of ultraviolet disinfection products ?

A.Many bacteria killed condition that needs a certain temperature and a certain amount of time, such as common, hepatitis b virus in above 120℃ for 20 minutes to kill. So the way water is boiled and boiled doesn’t kill germs completely. However, ultraviolet disinfection directly reaches the molecular structure of DNA or RNA in cells, which can achieve the effect of sterilization and disinfection more efficiently.

B.For example, traditional families will use cupboards and other storage tableware, but the traditional cupboards are not sealed or sealing is not good, will be dust sewage and insects, ants, rats and other secondary pollution. In addition, traditional crockery does not have drying function, the area with higher humidity, cost of woodiness tableware is easy moldy, and the aflatoxin in mould is a kind of bacterium that cause cancer, kill more different again, very big to hidden trouble of human body health. Use ultraviolet disinfection product to be able to undertake sterilization disinfection to the article that needs disinfection at any time and place.

|

| UV-LED CURING |

8.The relationship between the power of ultraviolet disinfectant products and the effect disinfectant area.

The small sized ultraviolet ray of 4W disinfects the lamp, reliable disinfection space is the space of 6 square meters. Because the space is small light can reflex nevertheless, antiseptic effect can increase 50% left and right sides.

12W is suitable for less than 20 square meters.

30W is suitable for within 20-35 square meters.

40W is suitable for within 30-45 square meters.

9.Life of Ultraviolet Lamp Tube

The effective life of hot cathode is 8000 hours, and that of cold cathode is over 20000 hours.

10.Lamp Material Classification of Ultraviolet Disinfection Products

Classification of Ultraviolet ray sterilization lamp tube : quartz glass tube, high borax glass tube, ordinary glass. The quartz glass tube material is actually a kind of low-pressure mercury lamp, like ordinary fluorescent lamp, uses low-pressure mercury vapor (<10, 2pa) to emit ultraviolet light after being excited. The lamp tube of general bactericidal lamp uses quartz glass to make. Because quartz glass has very high transmission ray to ultraviolet each wave band, amount to 80%, 90%. it is the best material that makes bactericidal lamp. Although quartz is more expensive, all mercury vapor lamps for UV polymerization are made of quartz and are usually made of bake-lite, plastic or ceramic.

The main reason is that quartz has three important properties very suitable for the production of ultraviolet lamp : 1). transparent to ultraviolet light, no absorption or very little absorption of UV. 2). it is a poor conductor of heat. 3). low thermal expansion coefficient, quartz purity and the presence of other trace compounds will affect the emission characteristics of lamp.

The tube is a fused quartz tube, the thickness of the tube wall is about 1mm, the outer diameter is 20~25mm, the total length of the arc lamp is 2m, the complex electrode layout (electronic emitter, base, conductor, etc.) is sealed at both ends of the quartz tube, the quartz tube contains mercury for transmitting energy and starting gas, usually argon. When the lamp is energized, an arc occurs between the poles. With the increase of voltage between electrodes, the temperature of the gas increases, and mercury evaporates, producing mercury vapor arc light and emitting characteristic ultraviolet light. When fully powered, the lamp also emits visible and partial infrared light.

Borax glass tube kind material, because cost concern and utility are different, also useful ultraviolet ray penetrates the borax glass tube that <50% to replace quartz glass. High boron glass production process and energy-saving lamps, so the cost is very low. But it is far from the performance of quartz glass tube ultraviolet sterilization lamp. Its sterilization effect has considerable different. The ultraviolet light intensity of high boron lamp tube is easy to attenuate, after lighting for hundreds of hours, the ultraviolet light intensity drops to the initial 50%,70%. However, after lighting 2000~3000 hours, the intensity of ultraviolet ray only reduced to 80%, 70% of the original, the light decline is far less than the high boron lamp.

Ordinary glass material is kind of ordinary glass with higher ultraviolet light, much higher than boron glass, slightly lower than quartz glass, light decay is still larger than quartz sterilization lamp, and can not produce ozone.

11.Ultraviolet allergy is right sunshine allergy namely, it is insolation that gets the ultraviolet ray in sunshine as a result of the skin, make the skin appears read swollen, SAO urticant wait for unusual reaction, cause skin allergy thereby. Generally speaking, the crowd of ultraviolet allergy is allergy sex constitution mostly. Accordingly, allergies can occur as long as the skin is exposed to a little sunlight. The symptom of ultraviolet allergy basically is the occurrence after the skin is basked in rad and swollen, burning, ache, SAO urticant, erythema, allergy is more serious, can appear even have a headache, systemic calorific, disgusting, lack of power, vomiting wait for unwell symptom. But the product of general ultraviolet sterilization disinfection can have protective layer, won’t produce an effect to this kind of crowd commonly.

12.How do ultraviolet sterilization lamps produce ozone ?

When the ultraviolet ray irradiates in the ray periphery to be able to produce the uneven electric ion, like this can cause the oxygen molecule in the air to produce the ionization, causes it to recombine into ozone.

13.The difference between UV LED and Mercury Lamp

UV LED has the advantages of high efficiency, energy saving, environmental protection and long life.

High efficiency : out-of-the-box, no need to preheat, can be set when the product after bright.

Energy saving : UV mercury lamp is a wide range of band, and the curing or sterilization of one of the main function is one of the wavelength. Other bands are useless, waste, absorbed by the product and converted into heat energy, this is also the product of mercury lamp irradiation than UV LED irradiation temperature higher. UV LED is a single wavelength, for UV coating, choose the matching LED wavelength curing. Compared with traditional UV mercury lamp, UV LED can save 60% energy.

Environmental Protection : mercury lamp contains mercury and other harmful substances, and the low-wave ultraviolet light in the mercury lamp will react oxygen in the air into ozone, which makes it necessary to install the exhaust system when using mercury lamp, and the long-wave ultraviolet light of mercury lamp is very large to the human radiation, need to be completely closed and shading treatment. UV LED environmental noise pollution, no harm to the human body.

Life : UV LED light source is cold light source with low calorific value. The life of UV LED is over 20,000 hours, while the life of mercury lamp is about 1,000 hours.

14.History of UV LED

UV LED is also called ultraviolet light emitting diode. The core part of UV LED is a chip composed of P-type semiconductor. There is a transition layer between P-type semiconductor and N-type semiconductor, which is called PN junction. In the PN junction of some semiconductor materials, the combination of the injected minority carries and majority carriers will release the excess energy in thee form of light, thus directly converting electrical energy into energy. The injection electroluminescent principle of the production of diodes called light-emitting diodes, commonly known as LED. When it is in a forward operating state (that is, both ends plus a positive voltage), the current from the LED anode to the cathode, semiconductor light-emitting diode in the history of what is it ?

Electroluminescence was first discovered on a piece of silicon carbide by Henry Joesph Round in 1907, but due to the dim light emitted and the difficulties in the silicon carbide experiment at that time, it was finally abandoned.

Further experiments were carried out in 1920 by German physicists Bernard Gooden and Robert Wichard Pohl, who obtained phosphorus from zinc sulfide doped with copper. But in the end the light wad so dim that it stopped again.

1936, George Destriau published a report on the luminescence of zinc sulfide power, which is widely credited with the term electroluminescence.

British scientists used gallium arsenide in the 1950s to create the first “modern” light-emitting diode in the early 1960s. The abbreviation of LED is light emitting diode. Its basic structure is a piece of electroluminescent semiconductor material, placed on a shelf with leads, and then sealed around with epoxy resin, to protect the internal core wire, so LED seismic performance is good.

Gallium phosphide itself was used as a luminescent material in the mid-1970s and soon gave off a very pale green light. Light-emitting diode using a gallium bisphosphate chip will be able to shine yellow. The yellow light-emitting diodes were made in Russia around this time using silicon carbide.

In the mid-1980s, gallium aluminum arsenide was used to make the first generation of ultra-bright light-emitting diodes, first red, then yellow and finally green.

In the early 1990s, indium gallium aluminum phosphorus was used to produce ultra-bright light-emitting diodes that emit orange-red, orange, yellow and green light. The first blue light-emitting diodes were also made in 1990 using silicon carbide.

It was only in the mid-1990s that gallium nitride was used to make ultra-bright blue light-emitting diodes, and it was soon by indium gallium nitride to make high-intensity green and blue light-emitting diodes. Ultra-bright blue light chips are the basis for white light-emitting diodes, which use a coating of fluorescent phosphorus that absorbs the blue light and emits it as white. The end result has always been to use the same technique to create any color.

15.So, what are the main features of UV LED as light-emitting diode ?

A.No or little organic solvent volatilizes, UV uses UV light source does not contain mercury, belongs to environmental protection product.

B.Because UV LED UV light can immediately ink curing, so it saves other technologies need drying time, greatly improve production efficiency.

C.Suitable for a variety of substrates : flexible or rigid, absorbable non-absorbent materials.

D.UV LED curing technology can also reduce the curing process of two-way drag phenomenon. In general, UV LED curing technology not only simplifies the printing process, but also enables end users who do not have screen printing knowledge to achieve the described printing effect.

E.UV LED curing system does not generate heat, UV LED technology can significantly reduce the heat generated during the curing process, so people can make UV printing on thin plastic and other materials.

F.Compared with traditional metal halide lamps, UV LED can save 2/3 of the energy. The service life of UV LED chip is many times that of traditional UV lamps. Another important advantage of UV LED technology is that UV LED does not need preheating and can be turned on or off at any time as required.

No comments:

Post a Comment