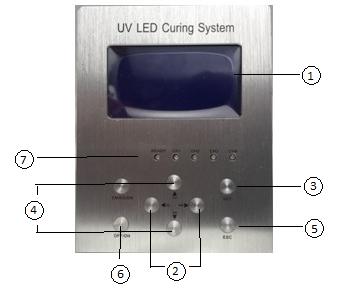

The Description of Spot Type UV Curing Machine Control Panel

①LCD

② ④Direction Key for setting function operation and as switch key of 4 lights (CH1/CH2/CH3/CH4)

③SET

⑤ESC: Exit and store the data in the device

⑥OFF/ON

⑦Function Light: when you are setting, the light is flickering.

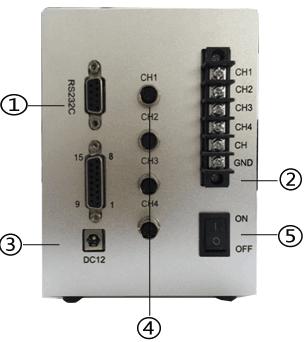

The Description of LED UV Spot Curing Machine Back Panel

①RS232 Connector ②Foot-switch Jack ③Electrical Socket Outlet ④ THE Lights Connector ⑤Power Switch

The Specification of UV LED Spot Light:

| Name | UV LED Spot Light Source |

| Type | HAO-TQ-BN-1219-1 |

| Wavelength | 365nm |

| UV Irradiation head | 1-4, fan cooling |

| UV Irradiation Mode | Round Spot 15mm |

| Irradiation Distance | 1-20mm |

| Operation Mode | AUTO MANU PULSE |

| Power | 0-100% |

| Light Intensity | 4000-9900mW/cm2 |

| Cooling Method | Pure Aluminum Shell Natural Cooling Fan Cooling |

| Supply Voltage | 7.5-36VDC |

| Power Consumption | 50VA |

| Ambient Temperature | +5- +40℃ |

| Ambient Humidity | 20-60% |

| Size | L: 166mm W: 100mm H: 138mm |

| Weight | 2.5kg |

Caution :

1.Package and Transport

When transporting equipment, use random packing materials. Any damage caused by improper packing equipment is not not under warranty.

2.Daily Use and Maintain

LED irradiation head is needed be cleaned regularly. Please use soft buckskin, lens paper and alcohol to clean, ensuring the irradiation intensity and good heat dissipation.

Cleaning the controller regularly. Please wipe with a little alcohol with a cleaning tool. In order to protect the surface of facility, don’t use the volatile liquid or having ammonium hydroxide ingredient to clean (diluent or benzene, etc.).

Attention :

Please do no unauthorized remove the controller and UV LED irradiation head, leading the product to work abnormally.

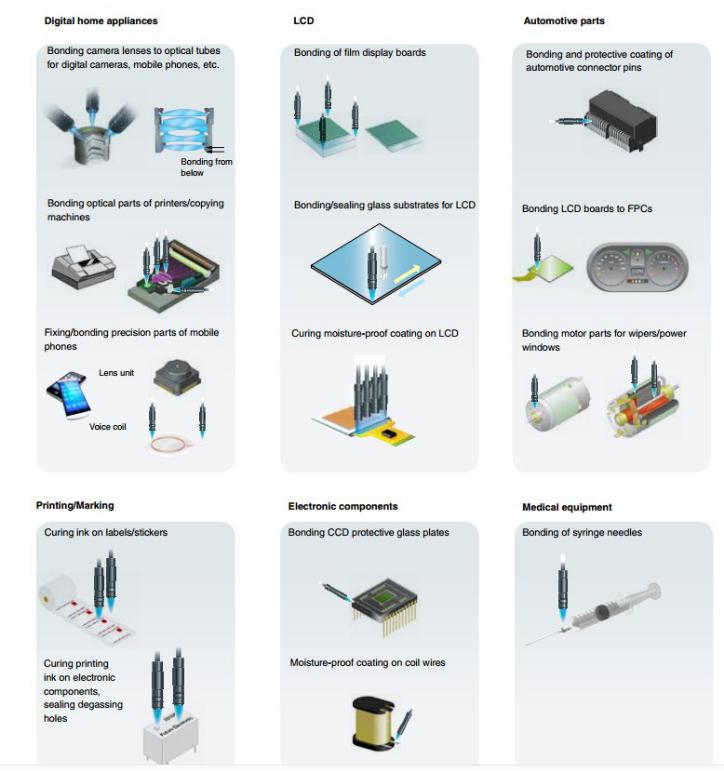

Which Filed is Suitable for Spot Type UV Light Source?

No comments:

Post a Comment