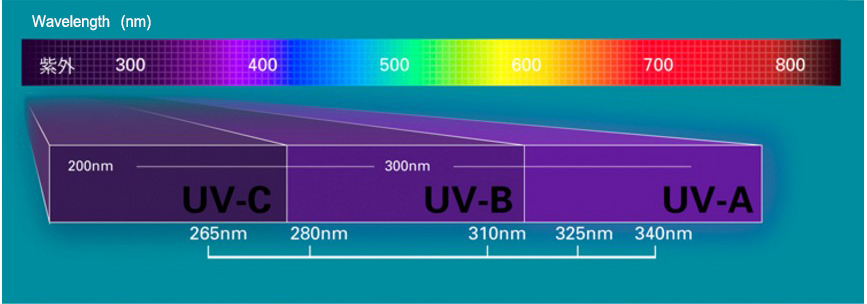

Before discussing High Efficiency 365nm UV LED Lights, we should clarify a few concepts and make sure that we are talking about the same time, so as to avoid any confusion between the two. In this case, UV refers to UV coating, UV ink, UV adhesive and other UV curing materials. LED refers to ultraviolet light source. UV-LED is defined as “UV material curing using ultraviolet LED light source as radiation source”.

As we all know, the curing light source used in the traditional UV coating is medium-high pressure mercury lamp. In the past two years, influenced by the policy factors such as energy saving and environmental protection, and also thanks to the rapid development of High Power UV Light Emitting Diode for UV Coating. It has the basis for industrial application. A upsurge of UV LED has been set off in the market. New things can always attract people’s attention and popularity. But as a practitioner, it is necessary to have a clear understanding of UV LED. Here, I share with you some of our experience in the field of UV LED research in the past two years.

Due to the change of light source (the difference between Best 365nm ULtraviolet LED Lights for 365nm UV Flashlight and mercury lamp will be discussed later). the formulation system of UV coating and the whole painting and curing process have been changed. For the UV LED system, from technology to market, we believe that there are five key research directions.

A.Difference between UV LED Light Source and Mercury Lamp (advantages and disadvantages, public misunderstanding of UV LED)

B.Achieve UV Curing Light Source for UV Material Parameters

C.The emitting principle of UV LED and the development status of UV LED chip

D.Research and development of UV Light Source System

A.The limitations of photo-initiators, thinking in terms of system, resins, monomers

B.To achieve UV LED curing coating formula and coating process design (initiator, resin, monomer, temperature, surface drying, drying, pigment, filler)

C.Different storage, transportation, construction conditions and construction process of the coating itself performance requirements

D.Different applications require different film properties

No comments:

Post a Comment