Product Details

Irradiation Single-Head UV LED Spot Light Source is portable, small thermal radiation, high enrgy, environmental protective, etc.. That is why so many customers choose UV LED Spot Light Source Machine, replaced traditional mercury lamp.

Parameters

Brand | UV-LED CURING | Type | 033B8W |

Illuminance | 8000mW/cm2 | Power Adapter | AC 0-250V |

Plug Interface | Two feet straight, international standard | Size | L: 115MM*W: 90MM*H: 55MM |

Weight | 0.2kg (including irradiation head, power cables) |

|

Irradiation Parameter

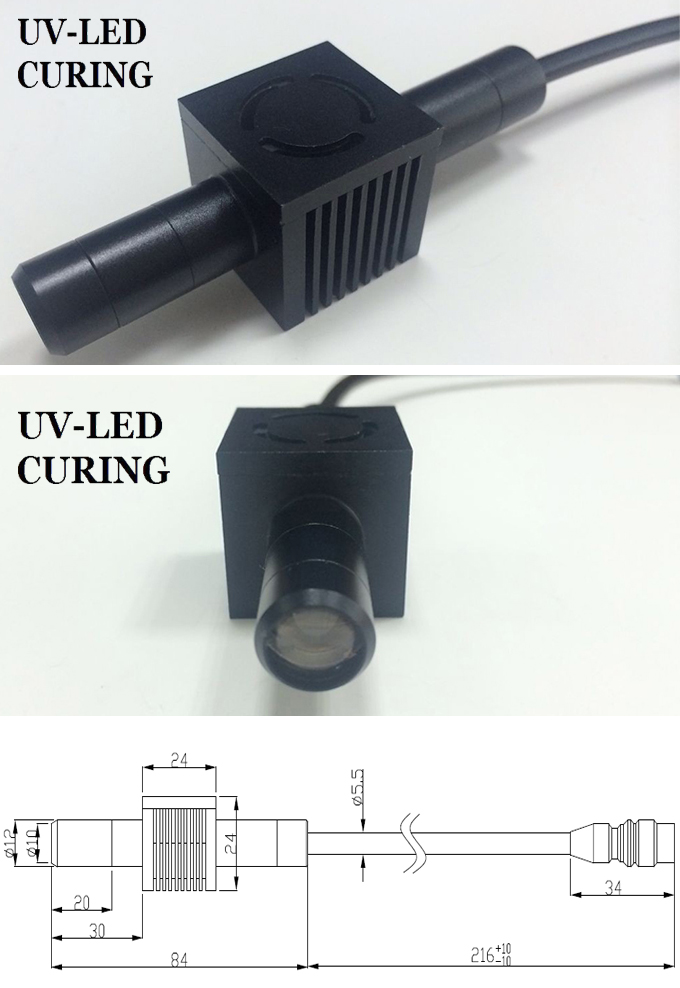

Cooling Method: Air Cooling

Line Length: 1.5-2m

Light Spot Size

Size: 12mm external diameter

Thread: M11*0.75

1. Round Spot: φ1.5mm,φ3mm,φ4mm,φ5mm,φ6mm,φ8mm,φ10mm,φ12mm,φ15mm,φ20mm

2. Direct Rectangular Light Spot:: 3*12mm,4*16mm,5*20mm

3. 90°a lens of side light (φ3mm, φ4mm,φ6mm,φ8mm, round spot)

Multiple lenses are selected for different spots. When changing, twist the lens of the inscribed part.

Shipment standard with one, can be multiple choice, optional extra.

Light of the Rectangular Lens

The size of different spots can affect the irradiation intensity. The smaller the light spot is, the higher the irradiation intensity is.

Spot Diameter | Irradiation | Irradiation |

1.5mm | 8800mW/cm2 | 7mm |

| 3mm | 6500mW/cm2 | 9mm |

| 4mm | 4800mW/cm2 | 14mm |

| 5mm | 4400mW/cm2 | 15mm |

| 6mm | 3400mW/cm2 | 17mm |

| 8mm | 1800mW/cm2 | 27mm |

| 10mm | 1150mW/cm2 | 25mm |

| 12mm | 800mW/cm2 | 25mm |

| 15mm | 550mW/cm2 | 38mm |

| 3*12mm | 1050mW/cm2 | 9mm |

| 4*16mm | 800mW/cm2 | 11mm |

| 5*20mm | 600mW/cm2 | 15mm |

Instructions

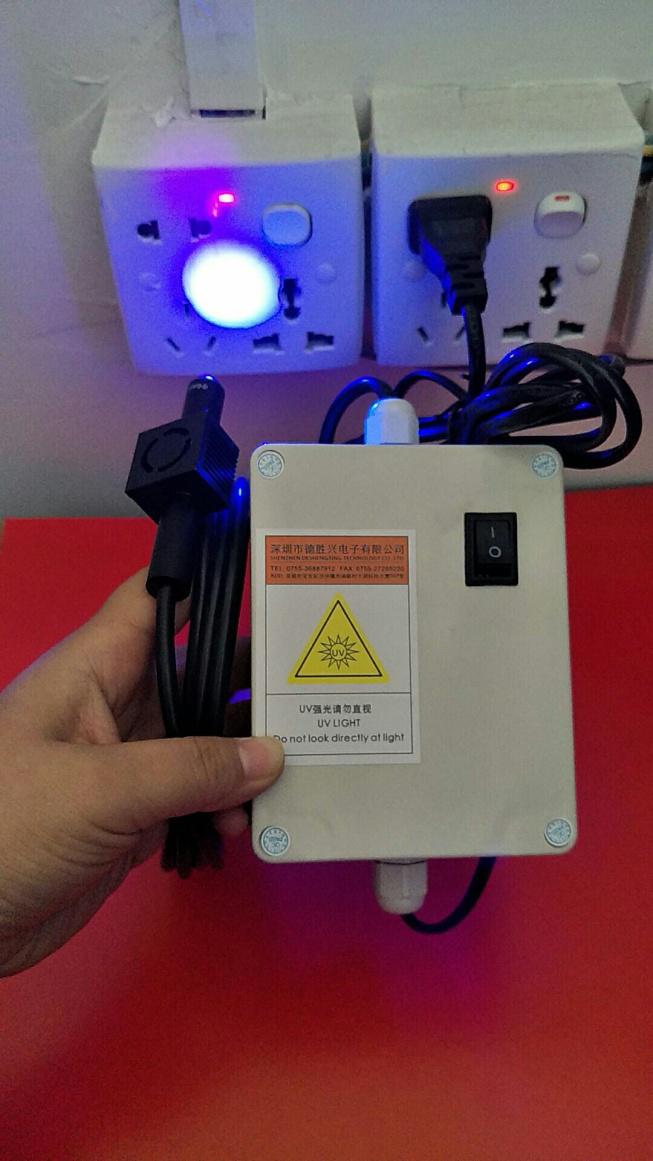

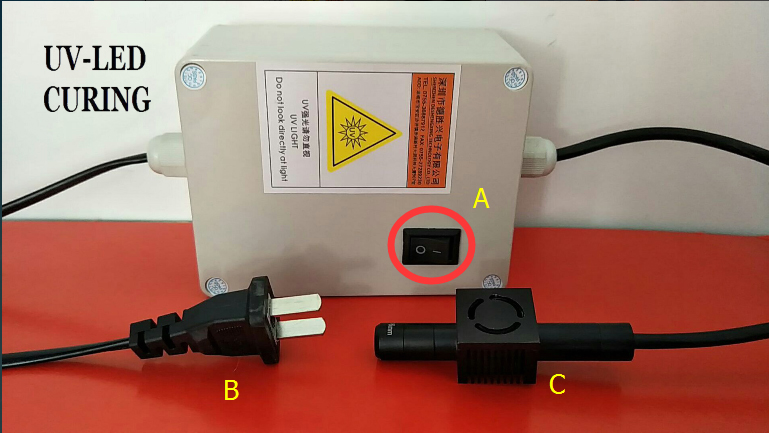

A. Power Switch B. International Standard Plug C. Fan Head

Operation:

Only one switch button operation. When using, just turn on the switch, and turn off the switch manually when not in use.

Application Area:

1. Hard disk head assembly (Read-write head packaging, gold wire fixation, bearing, coil, chip bonding and so on)

2. Assembly of motors and components (Wire, coil fixed, coil end fixed, PTC/NTC components bonding, protect transformer core)

3. DVD/Digital Camera (Lens, lens pasting, circuit board reinforcement)

4. Sensor production (Gas sensor, photoelectric sensor, optical fiber sensor, photoelectric encoder, etc.)

5. Assembly of cell phone components (Camera lens, receiver, microphone, shell, liquid crystal module, touch screen coating, etc.)

6. TFT-LCD liquid crystal panel import package

7. TFT-LCD pasting and packaging of LCD panel FPC

8. UV LED light curing application of PCB

9. UV LED light curing application of Optics Series

10. Optical element assembly (Lens group, prism, DLP optical engine assembly, CCD, COMS)

11. LED UV light curing application of optical communication industry

12. Optical communication industry components (All kinds of glass packaging structures are bonded or sealed, the fixation of tiny components, etc.. Such as PLC Branching Unit, WDM, AWG, etc.)

13. UV LED light curing application of Research Institutes

14. Medical device and medical accessories LED UV light source curing application

15. Capacitive touch screen adhered to curing

16. UV encapsulation and curing application of laser

Usage of U365nm

1. Fast curing adhesive glass and metal UV adhesive

2. Fast curing UV conformal coating on PCB

3. Rapid curing of UV ink on T-shirts

4. Instant cup bowl cover and other sterilization

5. Instant cure UV glue of adhesion disposable medical catheter, container or other medical equipment, and the equipment for high UV sterilization

6. Instant cure of all kinds of UV ink on plastic phone case

7. Instant cure UV glue between display surface and protective film of adhesive paper book

8. Instant cure UV glue for adhesion of various crystal, glass and other crafts, commemorative CARDS, key chains, and wood surface UV varnish

9. Replace the injection molding machine with the transfer printing technology, and quickly manufacture the precision plastic parts

10. Instant cure adhesion of all kinds of LCD glass and UV glue of its metal tube foot, and curing LCD end of UV sealant

11. Instant uniform cure adhesion of various touch screens and screen protector of UV glue

Advantages of UV LED Spot Light Source

1. Thermal radiation is small, the irradiating machine uses the luminescent part UV-LED power, the spectral wavelength is 365nm, no infrared light is emitted, so the surface of the irradiated product has no temperature rise.

2. High energy and high purity ultraviolet light is issued. The latest high energy UV LED is used to rapidly cure the UV glue and greatly improve the production efficiency.

3. To reduce the cost of consumables, the use time of UV LED can generally reach 30,000 to 40,000 hours, while the traditional LAMP system needs to replace the LAMP in about 2000 hours.

4. LED-UV spot light source adopts cable output, without optical fiber guide light. UV LED can reduce equipment cost and improve equipment utilization.

5. Energy saving and environmental protection, UV LED power consumption is low, and when used, no lamp tube is used to preheat, and it reaches 100% high power instantaneously, namely, out-of-the-box.

6. UV photoelectric conversion efficiency is high, and does not contain toxic mercury, also does not produce ozone, is a safer and more environmentally friendly alternative to traditional light sources.

7. The volume of the UV LED controller is about 1/8 of the volume of the traditional LAMP, which makes the installation of the equipment more simple. Small irradiation head design, because of fully consideration of the precise production space requirement, makes the equipment installation more convenient.

8. The equipment can be used in different process, according to the actual situation, the user can choose and match the extension cable.

9. Unique fan heat dissipation, fast heat removal of the chip, improving the stability of power output, extending the life of UV LED

Service Life

Compared with the traditional UV curing equipment, the mercury lamp has a lifetime of 800 to 3000 hours, and the service life of UV LED UV curing system reaches 30,000 to 40,000 hours. It can be lit only when theUV light is needed, and when DUIY=1/5 (when the preparation time =5 exposure time =1), the service life of LED mode is 30 to 40 times that of mercury lamp. Reduced time for replacing bulbs: improved productivity, and also very energy-efficient. Traditional mercury lamp curing equipment at work, because of the influence of mercury lamp start slow, open and close the light bulb life, must always light up, not only cause unnecessary power consumption and shortened the working life of the mercury lamp.

No Thermal Radiation

High power LED have no infrared emission, the surface of a product by illuminate below 5°C temperature.Traditional mercury lamp UV curing machine generally makes the surface of a product by illuminate rise 60-90 ° C, makes the product positioning displacement, bad product. UV LED curing mode is suitable for thermal sensitive, high - precision bonding process requirements, such as plastic base material, lens bonding and electronic products, fiber optic cable, etc..

The traditional mercury lamp curing machine adopts mercury lamp, the bulb contains mercury, waste disposal, is very troublesome of transportation, can cause serious pollution to the environment of improper handling. LED UV curing machine uses the semiconductor to discharge light, not to cause the environmental pollution factor. Therefore, using LED UV curing machine is more environmentally friendly.

Super Strong Illumination

With high power UV LED chip and special optical design, UV LED achieves high precision and high intensity

irradiation. The UV output reaches 8600mW/m2. Using the latest optical technology and manufacturing process, to achieve the better than traditional mercury lamp light output optimization of high strength and evenness, fast curing UV adhesives, shorten the production time, improves the production efficiency significantly, almost is traditional mercury lamp light luminosity of 2 times. When the traditional mercury light source curing machine increases the channel, the increase of the channel will result in the decrease of the output energy of the single irradiation channel. However, using LED UV irradiation, each irradiated head is independently illuminated, the irradiation energy is not affected by the increase of the channel and remains at the maximum. Compared with traditional mercury lamp, UV LED reduces the time of exposure and improves production efficiency.

Low Energy Consumption

UV LED is more than 10 times more effective luminous efficiency than traditional mercury lamp. At the same time, traditional mercury lamp needs continuous lighting work whether or not they are effectively irradiated, and the electricity is always in a state of consumption. Compared with it, UV LED power is consumed only when irradiated, and the power consumption is almost zero when standby. We can do a simple calculation. The power saved by each UV LED Spot Light Source Curing Machine is 270W*8H*365Days=800 kilowatt-hour.Thus, it can be seen that the cost of electricity per year can be saved by a thousand yuan. Not only that, but by saving energy, each of these can indirectly reduce carbon dioxide emissions by 1.4 tons per year.

No comments:

Post a Comment