Product Details

Semi-Automatic UV LED Curing Equipment System is our newest product for highly efficient and cost-effective wafer curing. LED light-curing technology offers significant benefits over conventional lamp-based UV curing systems including lower operating costs and instant start-up for on-demand curing.

The DSX-UV-Tape-8 Series offers the same uniformity of UV exposure and fast curing times as semiautomatic high-end UV curing systems and generates a cool, low-temperature UV-A 365nm curing process while eliminating both ozone and mercury safety risks.

Parameters : | Type : | DSX-UV-Tape-8 | |||

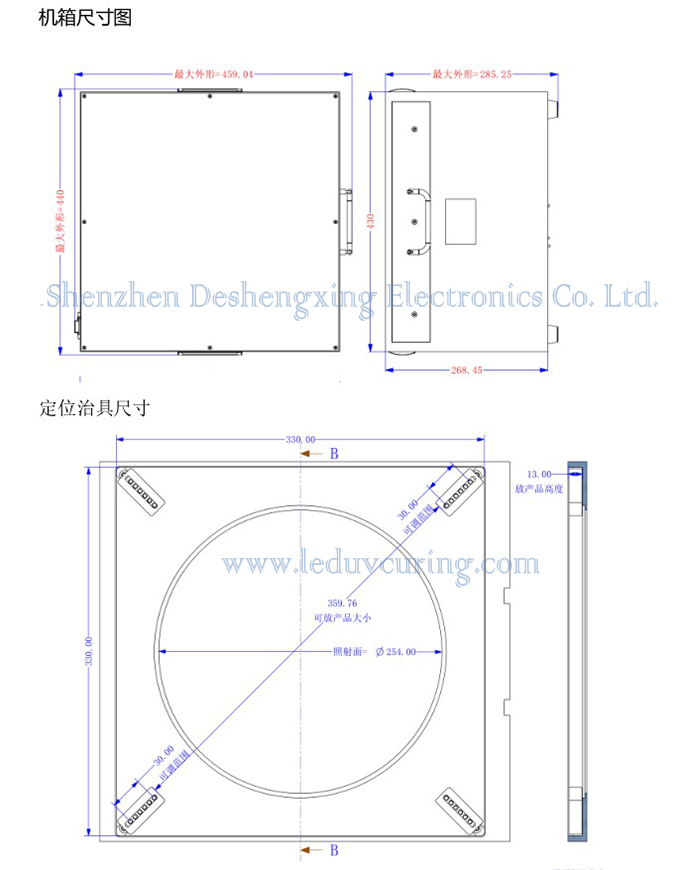

Outside dimension : | 459mm×440mm×286mm, can be customized | Drawer dimension : | 330*330*15 mm, can be customized | Lighting area : | Φ150mm, Φ200mm, Φ300mm |

Wavelength | 365nm-415nm selectable, 365nm convention | Peptization time | Depending on the characteristics of UV tape, minimum 5s | Material / Weight | White sheet metal / 30KG |

Rated voltage | AC 110/220V | Rated power | 350-900W | Frequency | 50/60 Hz |

Cooling method | Air cooling | Optical power | 1000W | Illuminance | >1000mW/cm2 |

Film type | UV Tape/UV film/UV wafer | Irradiation intensity | 20~100% adjustable | Timer | Time adjustable, unit : s, seconds |

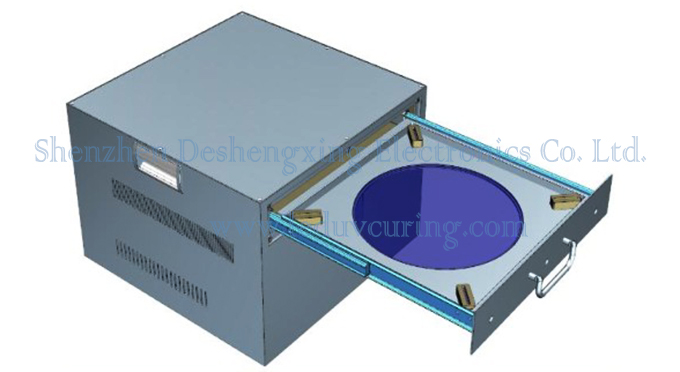

Thickness of the film | 0.15-3 mm | Illuminate way | Bottom-up irradiation | Control | Touch screen |

Function | Adjust time, intensity | Size of wafer | 6” 8” 10” 12‘’ selectable | Fixture Parts | 5.9 inches, can be customized |

Display / Language | Touch screen / English | Total Weight | 6.5KG | Manufacturer | Shenzhen Deshengxing Electronics Co., Ltd. |

Characteristics of UV Tape Curing Machine :

1.Small body, suitable for 6/8/10/12 inches irradiation

2.Adjustable time and brightness, touch screen operation, simple and convenient

3.Bottom-up irradiation, easy to place the wafer

4.LED cold light source, environmental protection products, with low temperature, uniform exposure, compact structure, small energy consumption, is the ideal model in semiconductor industry, and low temperature no damage to thermally sensitive materials.

5.The service life is more than 10 times longer than ordinary mercury lamp, continuous service life 15000-30000 hours.

6.Zero maintenance cost, no need to replace the illuminant parts for long-term work.

7.Closed light source design, no UV side leakage, no damage to the human body

No comments:

Post a Comment