Product Details

High Power UV LED Modules are made with High power UV LED. The LEDs are weldered on a PCB based on its wealth of experience in UV LED and thermal management.

This High Density UV LED Modules Chip can be used for curing of UV glue,UV ink, resin, adhesive materials. Also we can use it for any applications that need high power UV curing.

Key Features of Customized LED UV Light Chip for UV Curing :

- Best thermally conductive substrates: thick film silver layer on aluminum nitride, or DBC (directed

bonded copper) on aluminum nitride that enable the high-power density;

- Eutectic soldering process instead of silver epoxy for die attach, improving thermal conductivity;

- “Known Good Die”, good brand of UV chips that have been tested reliable with good statistics;

four wavelength ranges: 360 - 370nm; 380 – 390nm; 390 – 400nm; 400 – 410nm.

- Thermally stable and UV stable silicone for encapsulation that were selected based on extensive

experimental test data;

- Long history on packaging UV light source with rich experience and lessons.

Part Number Specification of 365-395nm Stabilized UV Light Module without Ozone :

| Part number | Wavelength range (nm) |

| MLUV40-360 | 360-365 |

| MLUV40-380 | 380-390 |

| MLUV40-390 | 390-400 |

| MLUV40-400 | 400-410 |

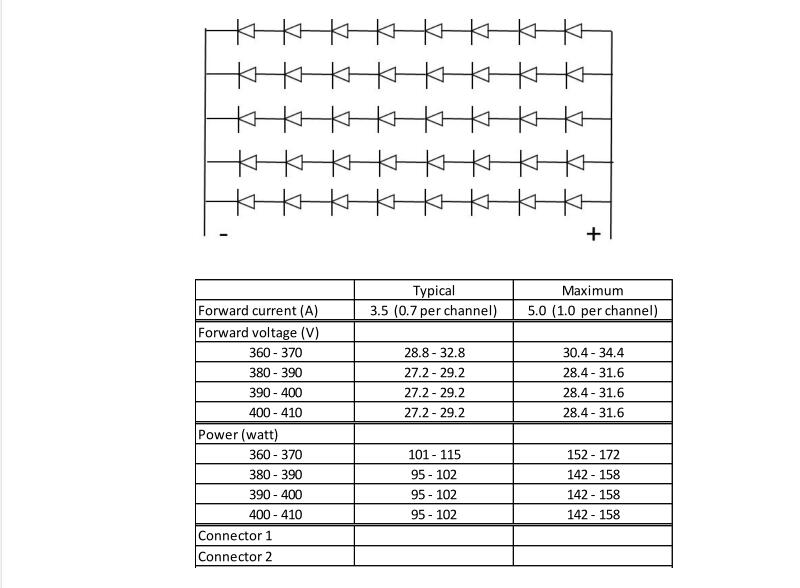

Absolute Maximum Rating of High Density LED UV Curing System Chip UV Lights :

DC forward current (A) | 5.0 (1.0 per channel) |

Power consumption (W) | |

360 - 370 | 150 |

380 - 390 | 140 |

390 - 400 | 140 |

400 - 410 | 140 |

LED junction temperature (°C) | 130 |

Operating ambient temperature (°C) | 50 |

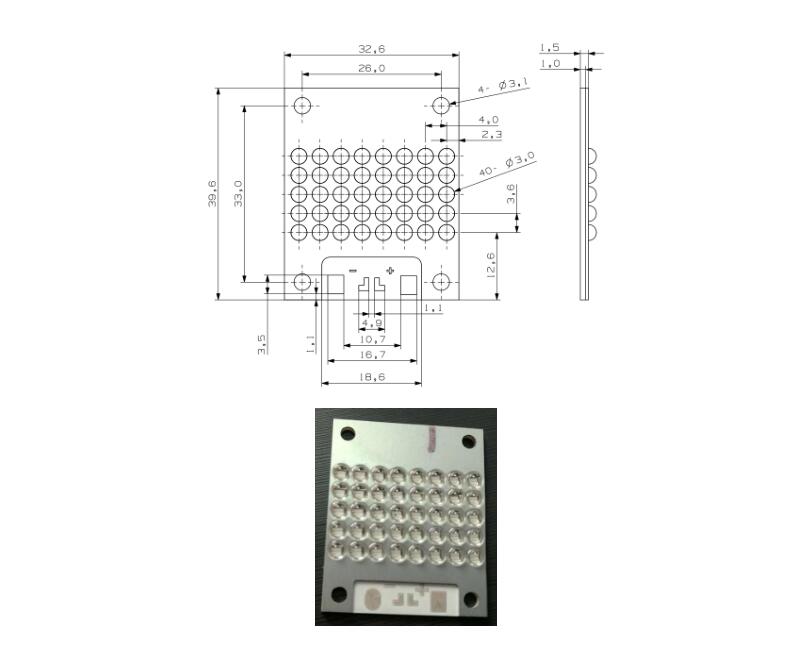

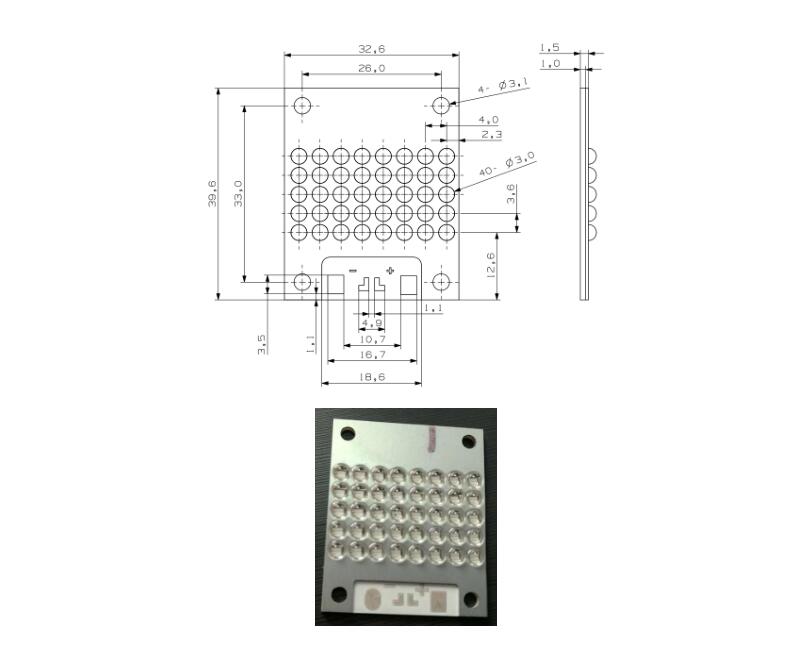

Mechanical Dimension of High Power UV LED Ultraviolet LED Chip Light :

| Dimension (mm x mm x mm) | 39.6 x 32.6 x 3.1 |

| Emitting area (mm x mm) | 31 x 19 |

Electrical Characteristics of Replaceable LED UV Light Module 365-395nm :

5 lines, each line has 8 LED chips connected in series; 5 lines are connected in parallel at the ends.

Optical Performance of Energy Saving LED UV Curing System Chip UV LEDs :

Peak wavelength (nm), @25C, @3.5A (0.7A per channel), note 1 | 360 - 370 |

| 380 - 390 | |

| 390 - 400 | |

| 400 - 410 | |

| FWHM (nm) | 15 |

| Radiant flux (W), @25°C, @3.5A (0.7A per channel) | Min. | Max. |

| 360 - 370 | 33.3 | 41.6 |

| 380 - 390 | 40.6 | 48.9 |

| 390 - 400 | 40.6 | 48.9 |

| 400 - 410 | 40.6 | 48.9 |

| Radiant flux (W), @25°C, @5A (1A per channel) | Min. | Max. |

| 360 - 370 | 46.4 | 59.2 |

| 380 - 390 | 57.6 | 70.4 |

| 390 - 400 | 57.6 | 70.4 |

| 400 - 410 | 57.6 | 70.4 |

Notes: 1. The peak wavelength is measured with an accuracy of ±1nm

Thermal Performance of High Peerformance UV Light LED Module for UV Curing :

Thermal Resistance (°C / W) | 0.13 |

Cautions of High Intensity UV Lamp Module Curing UV Ink:

1.UV LIGHT These devices are ultraviolet LEDs. During operation, the LED emits high intensity ultraviolet (UV) light, whichis harmful to skin and eyes.

2.UV light is hazardous to skin and may cause cancer. Avoid exposure to UV light when LED is operational.

3.Precautions must be taken to avoid looking directly at the UV light without the use of UV light protective glasses. 4.Do notlook directly at the front of the LED or at the LED’s lens when LED is operational.

No comments:

Post a Comment